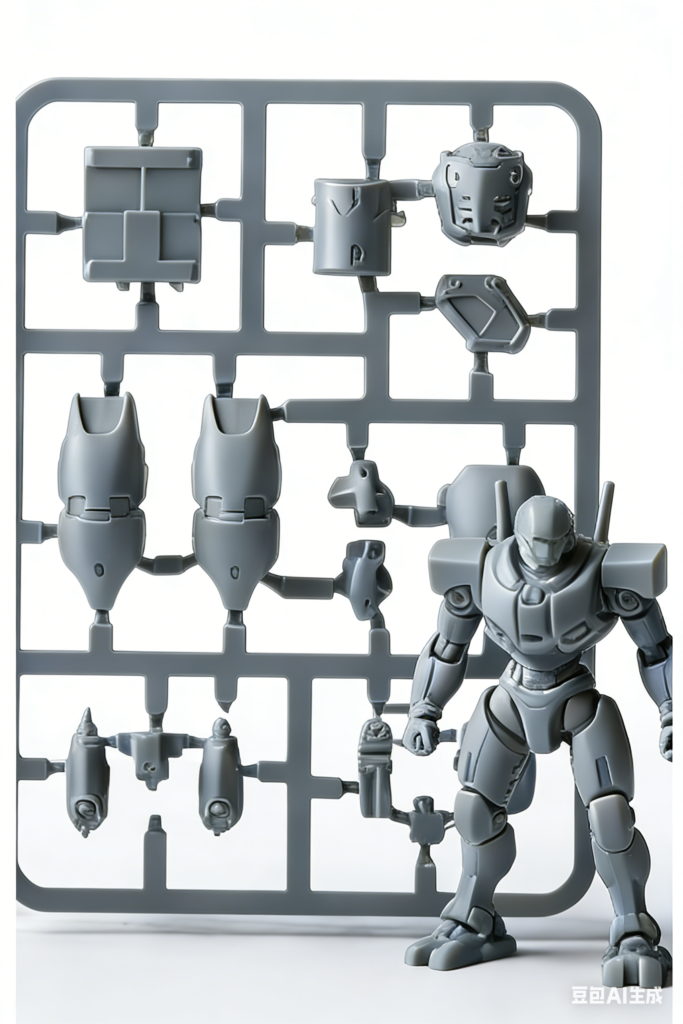

Custom Miniature

for Board Games & Tabletop Games

Custom miniatures are among the most technically demanding components in tabletop manufacturing. We provide end-to-end production solutions—from digital sculpt validation and mold optimization to high-volume mass production—engineered specifically for board games, skirmish games, and collector’s editions.

Our facility is equipped to manage complex mold undercuts and maintain structural strength across a range of materials. Whether producing retail-ready PVC or boutique-grade resin, we focus on controlled tolerances, consistent surface detail, and long-term paint durability, ensuring stable quality across large production runs.

We Provide All options for Custom Miniature

Custom Miniatures Sizes & Scale Standards

Miniature size and scale are foundational engineering decisions that directly impact mold complexity, material behavior, paint durability, and overall production cost. Defining scale early ensures visual consistency, structural stability, and efficient mass production across both core games and future expansions.

We work with publishers at the concept stage to translate artistic intent into manufacturable dimensions—balancing tabletop readability, durability during handling, and long-term production reliability.

Common Tabletop Scale Standards & Measurement Baselines

We support a wide range of industry-standard and custom miniature scales. To eliminate ambiguity during sculpting, prototyping, and tooling, scale selection is always paired with a clearly defined measurement baseline.

Industry-Standard Miniature Scales

Measurement Baselines: Eye-Level vs. Total Height

To ensure consistency across sculpts and expansions, we establish the measurement reference point at the start of each project:

Eye-Level Scaling (Industry Standard): Measured from the sole of the foot to the eye line. This method maintains anatomical consistency regardless of headgear, hair styles, or helmets and is preferred for humanoid figures.

Total Height Scaling: Measured to the highest point of the sculpt. Commonly used for monsters, creatures, or fixed-pose characters where vertical silhouette defines presence.

This clarification prevents scale drift between characters and avoids costly re-sculpting during validation.

Scale-Driven Engineering Constraints

Each scale introduces specific manufacturing considerations related to material flow, wall thickness, and minimum detail resolution:

Smaller scales require careful balance between sharp detail and reliable mold filling.

Larger miniatures demand controlled wall thickness to prevent sink marks, warping, or internal stress.

Thin elements—such as weapons, banners, or extended limbs—are structurally reinforced based on size, material choice, and expected handling frequency.

All sculpts are reviewed for undercut tolerance and long-term durability before tooling approval.

Base Integration & Tolerance Management

A miniature’s stability depends on the engineering precision of its base. We offer two primary configurations:

Integrated Bases: Molded as a single piece with the miniature for maximum strength and zero assembly requirements—ideal for mass-market board games.

Slot-Base & Socket Assemblies: Used for multi-part or hobby-style kits. Friction-fit tolerances are calibrated to remain secure even after paint application.

Consistency Across Core Games & Expansions

For expandable product lines, maintaining scale integrity is critical. We archive approved dimensions, tolerances, and tooling references to ensure future expansions remain visually and mechanically consistent with the original release—preventing scale drift across production runs.

Custom Miniatures Materials: PVC, Resin, and ABS

Selecting the right material for miniatures is a balance between surface detail, structural strength, and long-term durability during gameplay and shipping. We work with publishers early in the development process to match material performance with your game’s mechanical requirements, handling frequency, and fulfillment conditions.

High-Detail PVC (Polyvinyl Chloride)

PVC remains the industry standard for mass-market board game miniatures due to its flexibility and impact resistance. We utilize a controlled range of Shore hardness (typically 60A–90A) to balance fine detail with functional durability. Thin elements such as weapons or antennae are engineered to flex and recover without permanent deformation, while larger body sections maintain sufficient rigidity to preserve sculpt integrity during repeated handling and transport.

While PVC is cost-effective for high volumes, it is less suitable for multi-part hobbyist kits requiring manual glue assembly, as the surface bonding is less rigid than ABS.

Professional Resin Casting

Resin is the preferred material for boutique runs, limited editions, and high-detail collector miniatures. We use low-shrinkage thermoset resins capable of capturing sub-millimeter textures that exceed the practical limits of injection molding.

This process is ideal for intricate character sculpts and display-focused components, where maximum surface fidelity is prioritized over impact resistance. Recommended for print runs under 500 units to avoid the high cost of steel tooling.

ABS (Acrylonitrile Butadiene Styrene)

ABS is specified for assembly-ready “hard plastic” miniatures and multi-part kits. It provides superior edge definition, dimensional stability, and consistent part tolerances, making it the material of choice for tactical wargames and hobbyist-focused products. ABS components hold sharp details and clean parting lines, enabling precise assembly, reliable bonding, and long-term structural performance.

While ABS delivers exceptional sharpness and dimensional stability, it lacks the flexibility of PVC. Under extreme stress, components are more likely to fracture rather than bend, making ABS less suitable for games intended for younger or casual players with frequent rough handling.

Custom Miniatures Color & Surface Finishing

Color treatment affects visual clarity, wear resistance, and perceived product value. We offer scalable coloring and surface finishing options designed to align with production volume, budget, and intended gameplay handling.

Hand Painting

For premium editions and collector-focused releases, we manage professional hand-painting workflows using non-toxic, lead-free acrylic paints that comply with international safety standards. Our painting lines are calibrated for color accuracy, layer thickness, and drying control, ensuring consistent results across large production runs while preserving fine sculpt details.

For projects requiring enhanced depth without full hand painting, we also support controlled wash and shading techniques(Sundrop & Zenithal Priming) integrated into standard finishing workflows.

Solid Color Injection & Material Tinting

For high-volume projects, components can be produced using solid-color injection with precise Pantone Matching System (PMS) control. This approach ensures batch-to-batch color consistency and eliminates paint wear during gameplay. Advanced options include translucent materials, metallic flakes, and custom compound blends to achieve distinctive visual identities without post-production painting.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

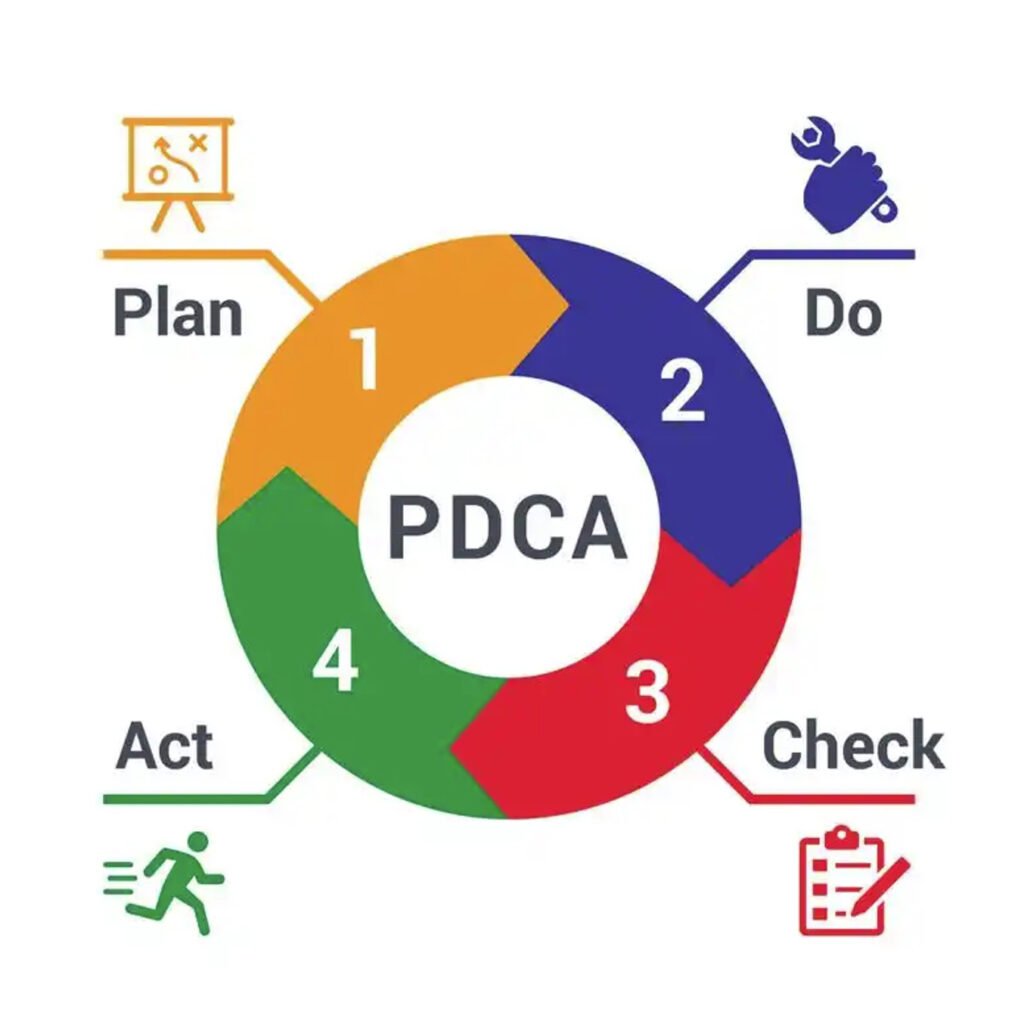

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Prototyping & First-Article Inspection (FAI)

The transition from a digital sculpt to mass-produced miniatures follows a structured, multi-stage verification process. Each stage is designed to identify and eliminate geometric, structural, or material risks before committing to high-cost steel tooling and full-scale production. This tiered approach ensures that what you approve digitally is exactly what ships to players—at scale.

Mass Production & Quality Control

Once the First-Article Inspection (FAI) is approved, production transitions into a tightly controlled, repeatable manufacturing phase. Our mass-production workflows are engineered to scale from thousands to multi-million units while preserving sculpt accuracy, structural integrity, and surface quality defined by the Golden Sample.

Automated Injection Molding & Process Control

We operate high-tonnage injection molding presses calibrated for multi-cavity tooling and long-cycle stability.

Key process controls include:

- High Clamping Force Calibration: Ensures complete cavity filling while eliminating flash, short shots, and edge deformation—essential for achieving fine surface detail and handling thin elements.

- Cycle-Time & Temperature Stability: Injection pressure, melt temperature, and cooling cycles are continuously monitored to maintain consistent part geometry across extended production runs.

- Cavity-to-Cavity Consistency: Multi-cavity molds are carefully balanced and thoroughly validated to ensure that every part meets the same dimensional and surface quality standards.

Assembly, Bonding & Structural Integrity

For miniatures requiring multiple components or complex poses, assembly is executed under defined structural standards.

We apply:

- Ultrasonic Welding: Used where possible to create permanent, seamless joints without adhesives—ideal for high-stress connection points.

- Precision Manual Bonding: When ultrasonic welding is not suitable, industrial-grade adhesives are applied under controlled conditions to ensure clean joints without visible residue.

All assembled units undergo pull-strength and alignment checks to verify long-term durability during handling, packing, and gameplay.

In-Line Quality Inspection & Batch Control

Quality control is embedded throughout the production process—not isolated at the end.

Our inspection protocol includes:

- In-Process Visual & Dimensional Checks: Sampling at defined intervals to monitor surface detail, parting lines, and deformation.

- Golden Sample Referencing: All inspections are benchmarked against the approved FAI sample to prevent drift over extended runs.

- Traceable Batch Segmentation: Each production batch is logged for material, tooling, and cycle parameters to ensure accountability and repeatability.

Regulatory Compliance & Safety Certification

Every production batch is tested to meet international toy safety standards, including:

- EN71-1 / EN71-2 / EN71-3 (EU)

- ASTM F963 (US)

All materials are verified as non-toxic, lead-free, and phthalate-free, and a Certificate of Compliance (CoC) is issued for each production run—supporting customs clearance, retail onboarding, and Kickstarter fulfillment requirements.

Factors Influencing Unit Cost

A combination of engineering decisions, material usage, and production efficiency determines the unit cost of custom miniatures. Strategic optimization during the design and validation stages can significantly reduce per-unit cost without compromising sculpt fidelity or durability.

Tooling Complexity & Mold Engineering

Steel tooling represents the largest upfront investment in miniature manufacturing. Key cost drivers include:

Undercuts & Mold Slides: Miniatures with deep undercuts, overlapping armor, or complex silhouettes require side-actions (slides) and removable inserts within the mold. Each additional slide increases tooling complexity, maintenance requirements, and tooling cost.

Cavity Count & Mold Structure: Higher cavity counts reduce unit cost at scale but increase initial tooling investment. We balance cavity design against expected production volume to optimize long-term cost efficiency.

Part Count, Assembly & Labor Intensity

The number of individual parts directly impacts both production speed and labor cost.

Single-Piece Miniatures: Most cost-efficient option. Eliminates assembly labor and minimizes structural risk during shipping.

Multi-Part Assemblies: Required for dynamic poses, large figures, or hobby-style kits. These increase unit cost due to manual assembly, bonding, alignment checks, and additional quality inspection steps.

Assembly strategy is evaluated during DFM review to ensure complexity is justified by gameplay or aesthetic value.

Scale, Weight & Material Consumption

Material usage is a linear driver of unit cost and logistics efficiency.

Scale Selection: Larger scales (e.g., 35mm vs. 28mm) increase material volume, cycle time, and packing density—impacting both production and freight costs.

Part Weight (Gram Weight): Heavier miniatures consume more raw material and require longer cooling cycles, directly affecting throughput and per-unit pricing.

We optimize internal wall thickness and structural geometry to reduce weight without compromising strength or surface detail.

Production Volume & Economies of Scale

Unit cost decreases as production volume increases.

High-Volume Runs: Benefit from amortized tooling costs, optimized cycle times, and automated process efficiency.

Low-Volume or Boutique Runs: Favor resin or soft-tooling solutions where tooling investment can be minimized, even if per-unit cost is higher.

We align material selection and tooling strategy with your expected sales volume to achieve the most cost-effective production model.

Cost Optimization Through Early Engineering

The most effective cost savings occur before tooling begins. Early decisions regarding pose complexity, scale, part segmentation, and material choice have a greater impact on final pricing than late-stage adjustments.

Our engineering team works directly with publishers during the prototyping and validation phases to identify cost-saving opportunities while preserving the intended gameplay experience and visual identity.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!