Custom Meeples

for Board Games & Tabletop Games

Meeples are player-facing identity components. Their shape recognition, handling comfort, durability, and visual differentiation directly influence player interaction, table readability, and long-term usability.

At Funway, meeples are manufactured as functional system components, not decorative figures. Material selection, profile geometry, and finishing methods are defined to support consistent handling, repeatable production, and reliable integration with boards, tokens, and storage systems.

We Provide All options for Custom Meeples

Meeple Materials & Component Systems

Material choice defines tactile feel, durability, visual clarity, and production efficiency. We guide meeple selection based on gameplay intensity, interaction frequency, aesthetic goals, and budget constraints.

Wooden Meeples (The Industry Standard)

Best For: Euro-style strategy games, family games, abstract mechanics, and high-count player sets.

Wood remains the most widely used meeple material due to its balance of cost efficiency, tactile warmth, and visual clarity.

Engineering Focus: We control grain orientation and moisture content to prevent warping, splitting, or dimensional drift during production and shipping.

Material: Birch, beech, or sustainable composite wood.

Key Properties:

Lightweight with warm tactile response

Stable handling for frequent player interaction

Natural grain variation enhances visual distinction

Manufacturing Notes:

CNC shaping or precision die cutting

Moisture content controlled within 8%–10%

Laser engraving or surface printing for symbols and details

Injection-Molded Plastic Meeples (ABS / PS)

Best For: High-frequency handling, complex silhouettes, and color-differentiated player pieces.

Plastic meeples allow greater shape flexibility and color consistency, making them suitable for games requiring frequent movement or detailed player differentiation.

Engineering Focus: Profile symmetry and controlled shrink behavior are prioritized to ensure consistent fit and stable standing.

Material Options:

ABS: Higher rigidity and impact resistance

PS: Improved detail clarity for fine profiles

Key Properties:

High dimensional repeatability

Strong edge and impact resistance

Uniform color through pigment-compounded material

Manufacturing Notes:

Multi-cavity steel molds

Gate placement optimized to avoid visible marks on key faces

Suitable for medium to high production volumes

Acrylic Meeples (Limited Applications)

Best For: Deluxe editions, high-visibility player markers, and display-oriented components.

Acrylic meeples provide a premium visual effect with transparency or color saturation but require tighter process control.

Engineering Focus: Edge quality and internal stress management are critical to prevent cracking or chipping.

Material: Optical-grade PMMA (acrylic).

Key Properties:

High optical clarity

Higher surface hardness than ABS

Manufacturing Constraints:

Narrower processing window

Edge polishing required for consistent appearance

Not recommended for very high-count or high-impact use

Meeple Sizes, Profiles & Selection Considerations

Meeple selection is driven more by footprint size and profile clarity than precise thickness.

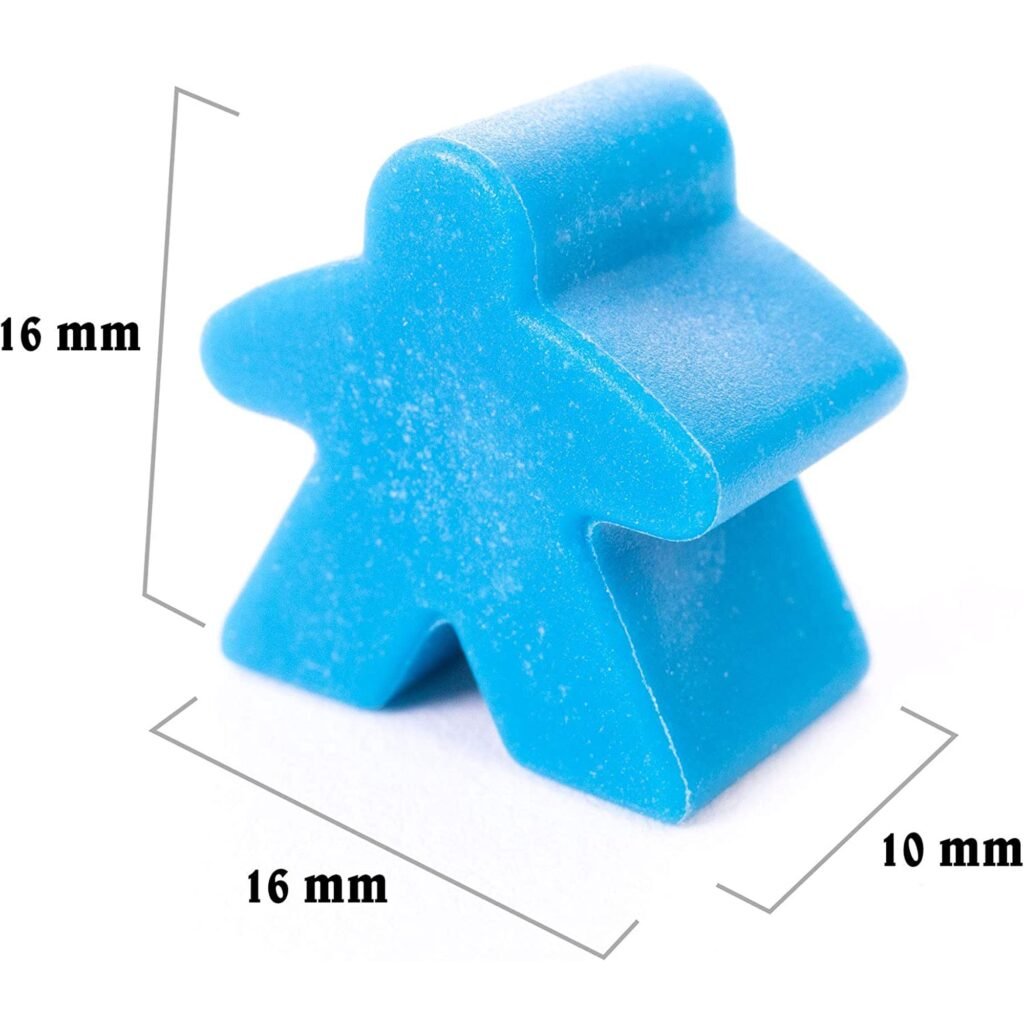

Common Size Ranges:

12–15 mm height – Compact games or dense boards

16–20 mm height – Standard board game applications

20 mm+ – High-visibility or feature pieces

Selection Considerations:

Larger profiles improve table visibility but increase material usage and storage space

Narrow bases may require stability review to prevent tipping

Wooden meeples are typically specified by overall height and base footprint, with thickness adjusted based on shape and material

Meeple Shape Variants & Gameplay Applications

Meeple geometry influences recognition speed, stability, and wear patterns.

Classic Meeple Silhouette: Used for player identity and ownership tracking. Symmetrical profile ensures stable standing and easy recognition.

Role-Specific or Thematic Shapes: Applied in games with asymmetric factions or character roles. Shape feasibility is reviewed to maintain structural strength at narrow points.

Minimalist Markers: Simplified profiles for abstract or information-dense games. Prioritizes clarity and compact storage.

Custom Silhouettes: Designed for unique mechanics or branding. Each profile undergoes feasibility review to confirm durability, balance, and production repeatability.

Color Application & Surface Finishing

Color and finishing choices affect player differentiation, wear resistance, and unit cost.

Color Methods

Color application methods are selected based on material system, durability expectations, and visual contrast requirements. Not all color processes are compatible with every material.

Solid-Color Staining or Painting

- Applied to wooden meeples.

- Color is absorbed into or bonded onto the wood surface, preserving grain visibility while providing player differentiation.

- Trade-off: Natural appearance with moderate wear resistance under frequent handling.

Pigment-Compounded Plastics

- Used for injection-molded plastic meeples.

- Color pigments are mixed directly into raw plastic material before molding, resulting in uniform color throughout the part.

- Trade-off: High color consistency and wear resistance, with limited post-mold color changes.

Transparent or Tinted Acrylic Materials

- Applied to acrylic meeples.

- Color is introduced at the material level to maintain optical clarity and light transmission.

- Trade-off: High visual impact with increased material and finishing cost.

Marking & Details

Marking methods are selected based on material type, durability requirements, and visual contrast. Not all marking techniques are suitable for every material system.

Laser Engraving

- Best suited for wooden and acrylic meeples.

- Provides permanent markings without added ink layers. Engraving depth and contrast depend on material color and surface finish.

Pad Printing

- Used primarily on plastic meeples for high-contrast icons and multi-color details.

- Ink adhesion and wear resistance are controlled through surface preparation and curing.

Silk-Screen Printing

- Applied to wooden meeples with flat or slightly curved faces.

- Suitable for bold symbols and color fills with controlled wear characteristics.

Surface Protection

Surface protection methods are selected to balance wear resistance, handling comfort, and production cost.

Non-Toxic Sealants

- Applied to wooden meeples.

- Sealants protect against moisture absorption, color fading, and surface wear while remaining safe for frequent hand contact.

Scratch-Resistant Finishes

- Applied to plastic and acrylic components.

- Protective coatings improve resistance to scuffing and surface abrasion during gameplay and storage.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Tooling & Profile Engineering

Tooling approach is selected based on material system, order volume, and profile complexity. Tooling decisions directly affect upfront cost, per-unit pricing, and long-term repeatability.

Wooden Meeples

CNC tooling or precision cutting dies

Lower upfront tooling cost

Ideal for flat or moderately complex silhouettes

Injection-Molded Meeples

CNC-machined steel molds

Higher upfront tooling investment

Required for complex 3D profiles or high-volume consistency

Prototyping & First-Article Inspection (FAI)

Pre-production samples are produced to verify:

- Profile accuracy and stability

- Color consistency

- Fit with boards, tokens, and storage inserts

Approved FAI samples are retained as Golden Samples for batch-level and cavity-level production reference.

Mass Production & Quality Control

Meeple quality is maintained through process consistency, not post-production sorting.

Dimensional spot checks

Visual inspection for profile defects and finish quality

Stability and fit verification

All applicable materials comply with EN71 and ASTM F963 standards.

Cost Drivers & MOQ Optimization

Meeple unit cost is influenced by several controllable factors.

Material System

Wood is the most cost-efficient option

Plastic and acrylic increase material and tooling cost

Profile Complexity

Thin features or intricate silhouettes require tighter tooling control

Color & Finishing

Multi-color or protective coatings add processing steps

Order Volume

Higher volumes reduce unit cost through tooling amortization

For smaller projects, standard wooden shapes or shared tooling approaches can reduce upfront investment while maintaining visual differentiation

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!