Custom Game Tiles

for Board Games & Tabletop Games

Game tiles are information-dense, board-adjacent components. Their flatness, thickness consistency, edge durability, and surface readability directly affect board alignment, setup speed, and long-term usability.

At Funway, tiles are manufactured as functional and structural gameplay components, engineered for long-term tabletop performance, not decorative prints. Material systems, tooling methods, and finishing processes are selected to ensure tiles remain flat, readable, and dimensionally stable throughout commercial production and repeated play.

Reliable tile manufacturing depends on material-appropriate tooling, controlled lamination and cooling and process-driven quality control—ensuring that modular layouts remain visually continuous and mechanically sound across your entire game world

We Provide All options for Custom Game Tiles

Tile Materials & Component Systems

Material selection determines tile rigidity, surface clarity, wear resistance, and production efficiency. We guide tile material choices based on gameplay interaction patterns, visual density, and cost structure.

Cardboard Tiles (The Standard Punch Board Tiles)

Best For: Map tiles, terrain tiles, modular boards, and information-heavy components. Cardboard tiles are the most common tile system in modern board games, offering strong cost efficiency and excellent print fidelity.

Engineering Focus: We manage lamination balance and grain direction to prevent warping and edge fraying during punch-out and long-term storage.

Material: High-density greyboard with C2S art paper.

Key Properties:

Flat, stable surface for board alignment

Lightweight for large tile counts

High-resolution printed detail

Manufacturing Notes:

Multi-layer lamination with grain alignment control

Steel rule die-cut tooling optimized for clean edges

Common thickness: 2.0 mm / 2.5 mm / 3.0 mm

Injection-Molded Plastic Tiles

Best For: Durable terrain tiles, high-frequency handling components, and 3D-adjacent systems. Plastic tiles are specified where impact resistance, moisture stability, or long-term durability is required.

Engineering Focus: Flatness control and uniform cooling are critical to prevent warpage in large-surface molded parts.

Material Options:

ABS: Structural rigidity and impact resistance

PS: Improved surface detail clarity

Key Properties:

High dimensional repeatability

Strong edge durability

Moisture-resistant surface

Manufacturing Notes:

Multi-cavity or single-cavity steel molds (size dependent)

Gate placement engineered to avoid visible flow marks

Suitable for medium to high production volumes

Tile Sizes, Thicknesses & Selection Considerations

Tile selection is driven by board integration, handling frequency, and storage method.. Thickness selection should be based on how frequently tokens areTile selection is driven by board integration, handling frequency, and storage method.

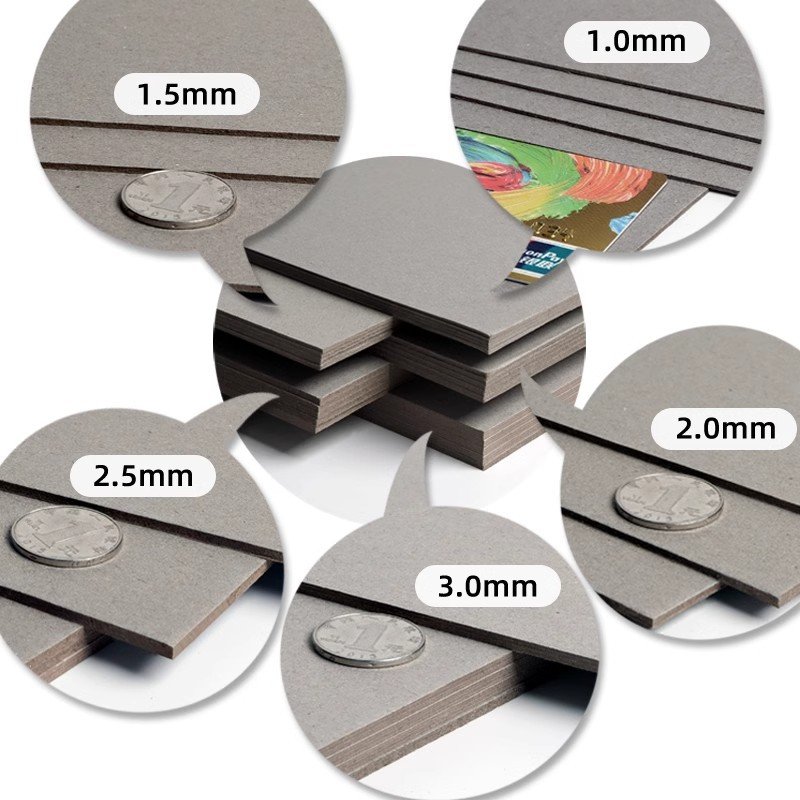

Common Thickness Options:

2.0 mm – Standard punch tiles for modular maps

2.5 mm – Improved rigidity for larger tiles

3.0 mm – Premium cardboard tiles or large-format components

Selection Considerations:

Thicker tiles improve flatness and durability but increase material cost and storage volume

Large tile footprints require tighter flatness control to ensure proper board alignment

Plastic tiles are typically specified by overall footprint size and structural thickness, rather than by standard punch thickness. reviewed for warpage risk during tooling.

Tile Shape Variants & Gameplay Applications

Tile geometry affects alignment accuracy, visual flow, and player interaction speed.

Square & Rectangular Tiles: Used for grids, modular boards, and area definition. Straight edges ensure clean alignment.

Hexagonal Tiles: Common in map-driven and territory-control games. Edge precision is critical to avoid cumulative misalignment.

Irregular or Organic Shapes: Used for terrain or thematic layouts. Shape feasibility is reviewed to ensure punch stability and edge durability.

Interlocking or Notched Tiles: Applied in fixed-layout systems. Requires tighter tooling tolerances and consistent thickness.

Color Application, Printing & Surface Finishing

Color and finishing choices affect player differentiation, wear resistance, and unit cost.

Color Methods

-Printed paper for cardboard tiles

-Pigment-compounded plastics for molded tiles

-Tinted or transparent acrylic materials

Marking & Graphics

Offset printing for high-detail cardboard artwork

Pad printing for plastic tiles

Surface Protection

Matte or gloss varnish for cardboard printed tiles

Scratch-resistant coatings for plastic and acrylic

Edge sealing to reduce long-term wear on punch tiles

Additional finishing steps improve durability but increase processing time and unit cost.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Tooling, Die-Cutting & Mold Selection

Tooling approach directly impacts upfront cost, unit price, and long-term repeatability.

Punch Board Tooling: Used for cardboard tiles

- Lower upfront tooling investment

- Ideal for high-count, flat components

- Fast setup and replacement

Injection Mold Tooling: Used for plastic or acrylic tiles

- Higher tooling cost

- Required for durability or 3D integration

- Lower unit cost at scale

Tooling selection is finalized during pre-production review based on volume, tile size, and durability requirements.

Prototyping & First-Article Inspection (FAI)

Pre-production samples are produced to validate:

Tile flatness and thickness consistency

Edge quality and punch behavior

Color accuracy and print alignment

Fit with boards, frames, and storage inserts

Approved FAI samples are retained as Golden Samples for ongoing production reference.

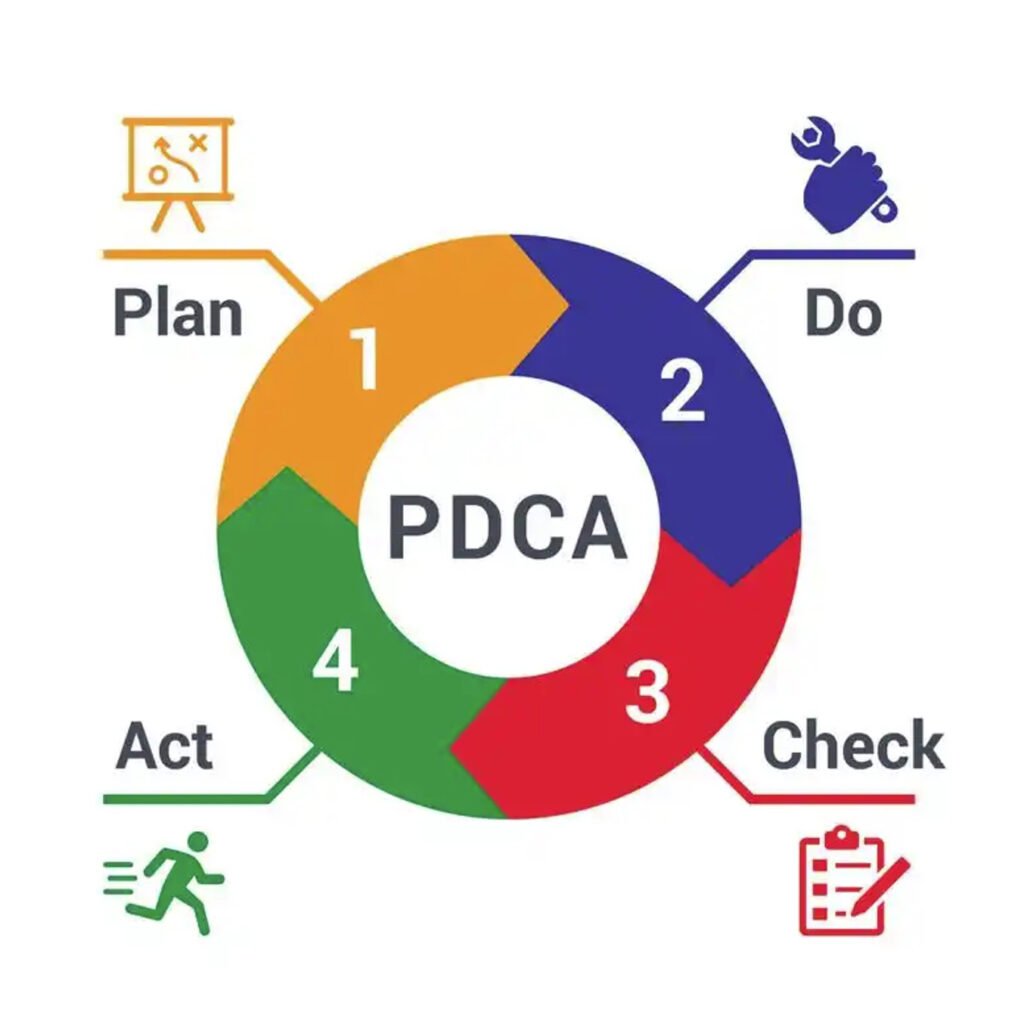

Mass Production & Quality Control

Tile quality is maintained through process control, not post-production correction.

In-process thickness and flatness checks

Visual inspection for edge defects and print offset

Assembly fit verification with boards and inserts

All applicable materials comply with EN71 and ASTM F963 standards.

Cost Drivers & MOQ Optimization

Tile unit cost is driven by several controllable variables.

Material System

Cardboard is the most cost-efficient option.

Plastic and acrylic increase material and tooling cost.

Tile Size & Thickness

Larger and thicker tiles require more material and tighter flatness control.

Printing & Finishing

Additional colors, coatings, or edge treatments add processing steps.

Order Volume

Higher volumes reduce unit cost through tooling amortization.

For smaller projects, shared punch layouts or standard tooling formats can reduce upfront cost while maintaining design flexibility.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!