Custom Game Pieces

for Board Games & Tabletop Games

Beyond the box and board, the physical components define how a game feels in the player’s hands. We manufacture custom game pieces using production-grade processes in metal, wood, and acrylic, converting original designs into repeatable, retail-ready components.

Our capabilities include FSC-certified wooden components, die-cast zinc alloy coins and markers, and laser-cut or CNC-machined acrylic pieces with controlled tolerances and consistent finishes. Each material is selected based on gameplay requirements such as weight, durability, surface wear, and visual clarity. All production runs follow strict quality control standards and comply with international safety regulations for global distribution.

We Provide All options for Custom Game Pieces

Specialized Material Solutions

Zinc Alloy Metal Coins & Sovereign Markers

Custom metal coins are the defining upgrade for Deluxe and Collector’s Edition board games. We manufacture zinc alloy game coins and markers using high-pressure die-casting, allowing for precise 3D relief, consistent thickness, and a balanced weight-to-size ratio that feels substantial without being oversized.

Engineering Profiles & Finishes: We support a wide range of surface treatments, including antique bronze and silver patinas, dual-tone electroplating, and enamel color infill. All coins are tumble-polished after casting to remove sharp edges, ensuring smooth handling and preventing abrasion to cards or boards during gameplay.

The “Clink” Factor: Metal density and alloy composition are carefully calibrated so each coin produces the distinctive metallic sound players associate with premium tabletop components—an often-overlooked sensory cue that reinforces perceived quality the moment the coins hit the table.

Sustainable Wooden Components & Hardwood Hardware

Wooden pieces offer an organic, “heritage” feel that synthetic materials cannot replicate. We specialize in high-precision woodturning and CNC milling to create functional game assets that are as durable as they are aesthetically pleasing. Typical applications include custom wooden meeples, dice, resource tokens, and scoring markers for strategy and family board games.

Material Selection & FSC Compliance: We source premium sustainable hardwoods, including Maple, Birch, and Beech, known for their tight grain and resistance to splintering. All timber can be sourced with FSC (Forest Stewardship Council) certification, ensuring your project meets the environmental expectations of modern eco-conscious backers.

Precision Finishing: Our components undergo a multi-stage tumbling and sanding process to eliminate burrs. We utilize non-toxic, lead-free water-based paints and lacquers that pass rigorous EN71-3 saliva and perspiration resistance tests.

Advanced Customization: Beyond simple shapes, we offer laser-engraving, silk-screening, and heat-transfer printing for intricate iconography. Our capabilities include custom-shaped resource markers, stackable building blocks, and interlocking structural pieces.

Precision Injection-Molded Plastic Components

For high-volume retail projects, injection molding remains the industrial standard for achieving perfect consistency and structural durability. We specialize in custom-tooled plastic components that range from complex resource markers to mechanical game assets, ensuring that the 50,000th unit is identical to the first approved sample. Typical applications include plastic game tokens, miniatures, dice, resource markers, and mechanical components for board games and tabletop products.

Material Engineering: We utilize high-impact ABS for superior surface finish and strength, Polypropylene (PP) for flexible components, and High-Density Polyethylene (HDPE) for parts requiring high wear resistance. All resins are virgin-grade and tested for long-term stability against UV exposure and environmental stress.

Tooling & DFM Precision: Every custom plastic piece undergoes a Design for Manufacturing (DFM) review to optimize wall thickness, parting lines, and gate placement. This rigorous engineering phase minimizes sink marks and ensures crisp, clean edges across all geometries.

Surface Treatments & Color Matching: We offer precise Pantone color matching (PMS), textured matte finishes, and high-gloss surfacing. For specialized sets, we can incorporate metallic pigments or multi-material “double-shot” molding to create distinct visual and tactile layers.

Precision-Machined Acrylic Standees & Components

Custom acrylic standees and game components offer a vibrant, modern alternative to traditional cardboard or injection-molded plastic. They are especially popular with indie publishers and Kickstarter creators who need high-fidelity artwork, consistent sizing, and low tooling costs for short or mid-volume production runs.

Manufacturing Process: We produce laser-cut acrylic components using industrial CO2 laser systems to achieve clean, burr-free edges with tight dimensional tolerances. Artwork is applied via high-speed UV flatbed printing, including optional “sandwich printing,” where graphics are sealed between acrylic layers to prevent scratching and surface wear during gameplay and transport.

Material Clarity & Grade: All components are manufactured using optical-grade cast acrylic, selected for its superior clarity, rigidity, and resistance to yellowing over time. This ensures standees remain crystal-clear, structurally stable, and visually striking even after years of handling and display.

Functional Sand Timers & Chronometer Hardware

Sand timers are precision mechanical components where consistency and durability are critical. We manufacture custom sand timers for board games and tabletop applications, integrating calibrated glass hourglasses into protective plastic or wooden housings designed for repeated handling.

Calibration & Accuracy Standards: Each production batch is tested to maintain a timing tolerance within ±5%, ensuring reliable performance for turn-based and real-time gameplay. Glass wall thickness and sealing strength are specified according to shipping method and fulfillment risk, reducing breakage during international logistics and last-mile delivery.

Customization & Cost Optimization: Timers are available in multiple standard durations (e.g., 30s, 60s, 90s), sand granularities, and color options. Custom frame designs, branding, and housing materials can be developed to match your game’s visual identity. For cost-sensitive projects, we also offer proven standard timer formats that significantly reduce unit cost while maintaining consistent timing performance.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Manufacturing Capabilities: Industrial Precision & Engineering

While material selection defines the look and feel of each game component, our manufacturing capabilities determine how accurately and consistently those components can be produced at scale. Below is an overview of the industrial processes that power our material solutions. Our manufacturing capabilities are built around industrial-grade processes specifically optimized for board game and tabletop components. From injection molding and CNC machining to laser cutting, die casting, and precision finishing, our production lines are engineered to translate complex designs into consistent, production-ready parts.

We manage tooling development, DFM validation, and material selection in-house, ensuring each component meets exact dimensional, durability, and safety requirements. This integrated engineering approach allows publishers to scale from prototypes to mass production with confidence, while maintaining strict quality control across every manufacturing stage.

High-Pressure Die Casting (Zinc Alloy)

Used primarily for metal coins and weighted tokens, our die-casting process utilizes high-pressure injection of molten zinc alloy into hardened steel molds.

Engineering Detail: We achieve high-relief 3D detailing with a tolerance of ±0.2mm. Post-casting, pieces undergo multi-stage centrifugal tumbling to ensure a burr-free, smooth tactile finish before plating.

Application: Premium currency, metal markers, and deluxe component upgrades.

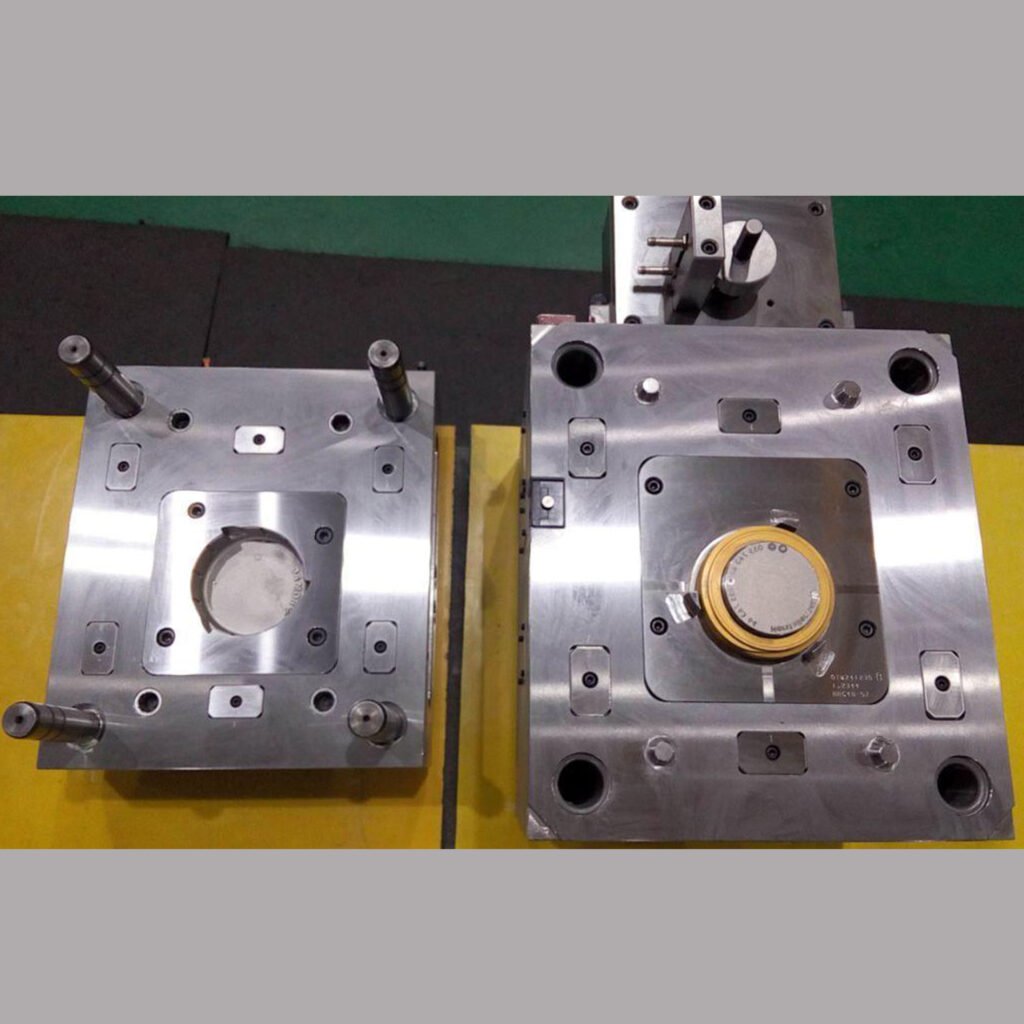

Precision Plastic Injection Molding

For high-volume production, we utilize automated injection molding presses ranging from 50 to 300 tons of clamping force.

DFM Integration: Every project begins with a Design for Manufacturing (DFM) analysis. We optimize gate locations and cooling cycles to eliminate common defects such as silver streaks, flash, or sink marks.

Tooling: We offer both aluminum “soft molds” for mid-range runs and hardened steel molds for multi-million unit lifecycles.

Industrial CNC Milling & Routing

CNC (Computer Numerical Control) is the bridge between digital design and physical hardwood or plastic components.

Capabilities: Our 3-axis and 5-axis CNC machines allow for complex geometric carving in solid wood (Beech, Maple) or high-density EVA foam. This process is ideal for creating structural game components that require high dimensional stability without the need for expensive molding.

Finish: Provides a clean, sharp-edged finish that is impossible to achieve with traditional manual carving.

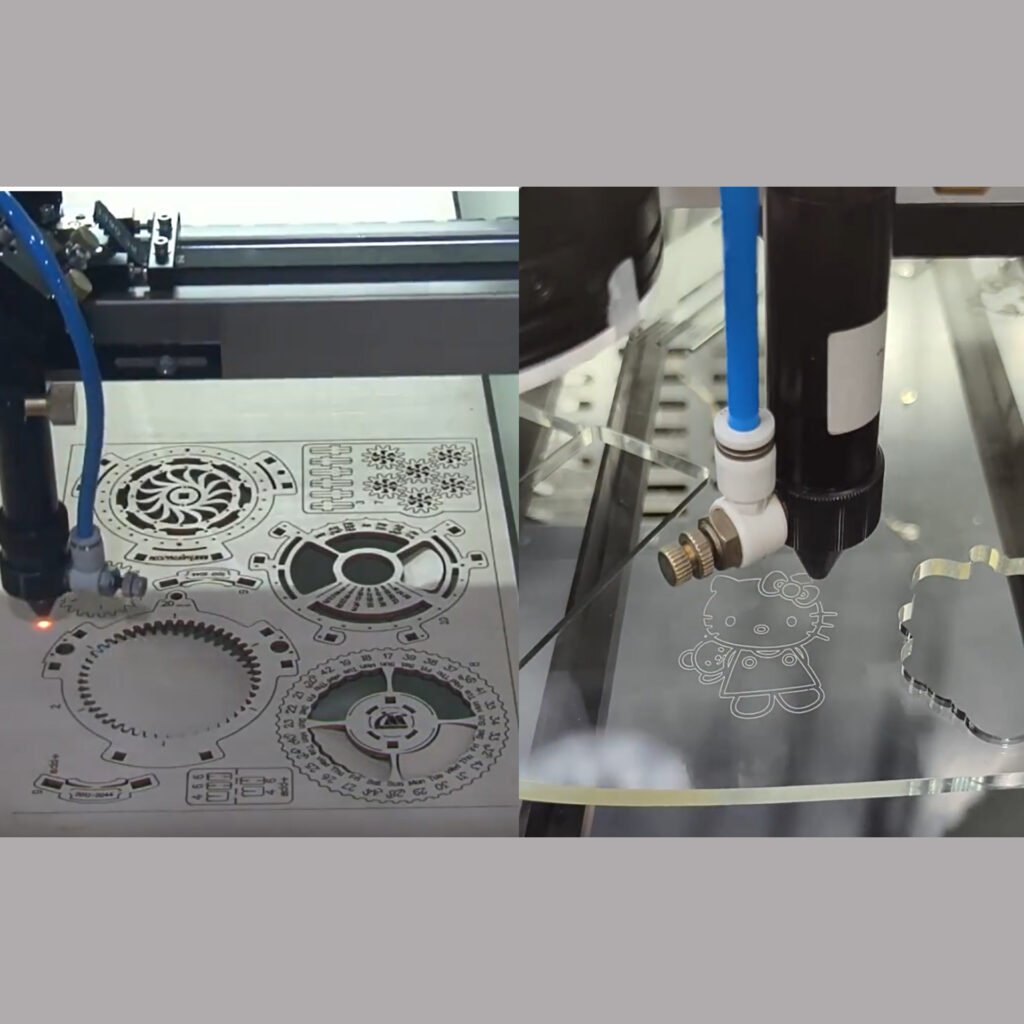

CO2 Laser Cutting & Precision Etching

For acrylic and thin-plywood components, laser technology provides unmatched speed and edge clarity.

Edge Quality: Our lasers are calibrated to produce flame-polished edges on acrylic, eliminating the need for secondary manual polishing.

Etching: We offer high-speed raster engraving for permanent iconography that will never fade or peel, providing a durable alternative to surface printing.

Manufacturing Rigor: Compliance & Logistics

Token unit cost is determined by a limited number of controllable variables.

Chemical & Physical Compliance

Distributing games in the US and EU requires strict adherence to safety standards. Our game pieces are tested for total lead, phthalates, and physical choking hazards under EN71-1/2/3 and ASTM F963. We provide a “Certificate of Compliance” for every production run to ensure seamless customs clearance and retail entry.

Fulfillment-Ready Packaging

We understand that small pieces are a logistics challenge. We offer automated bagging, custom tuck boxes for components, or pre-sorted kits to streamline your fulfillment center’s workflow. This reduces the risk of “missing pieces” claims from your Kickstarter backers.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!