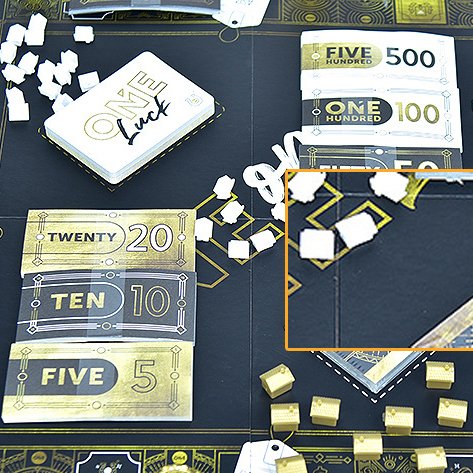

Custom Game Board Manufacturer

The game board is the heart of your tabletop project. At Funway, we provide professional-grade custom game board manufacturing services tailored to game designers, indie publishers, and Kickstarter creators. Whether you need a standard bi-fold or an expansive world map, we turn your artwork into a retail-ready masterpiece with expert die-cutting and seamless hinges.

We Provide All options for Custom Game Boards

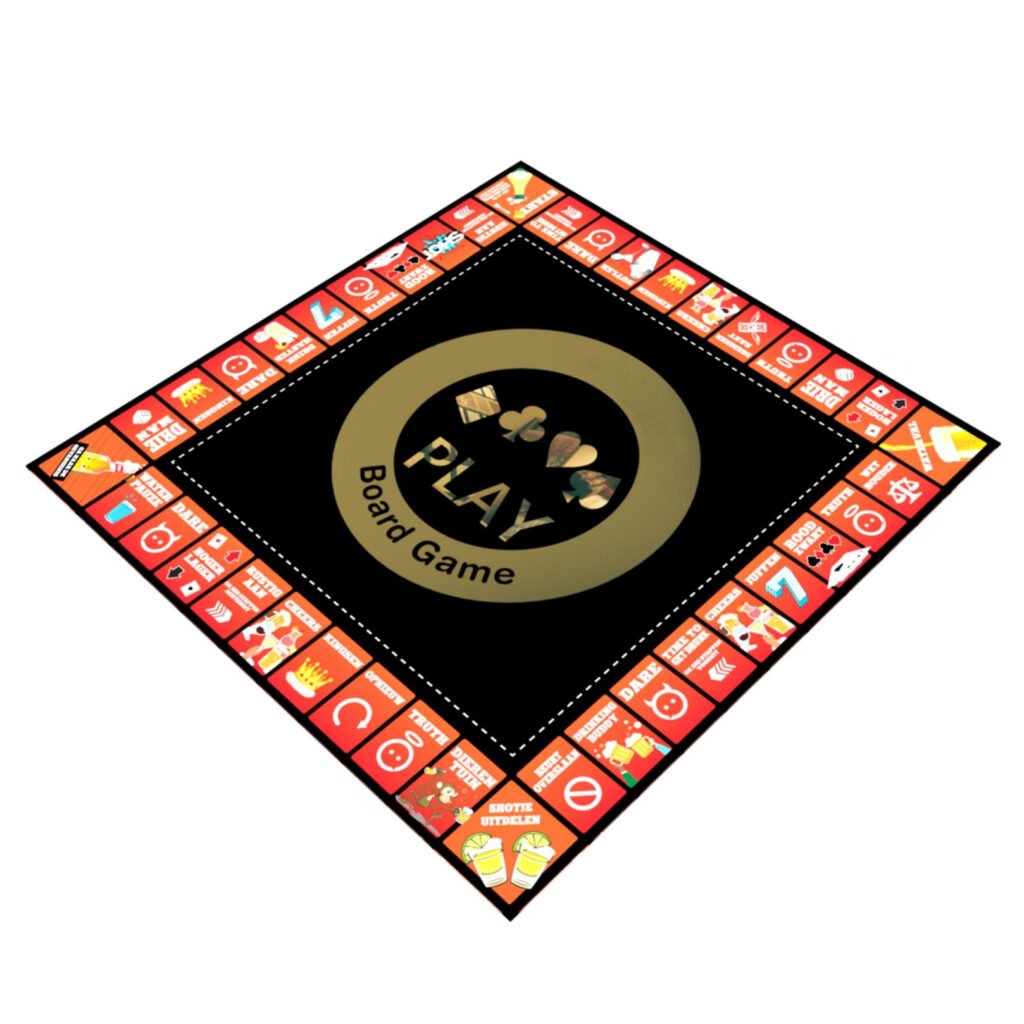

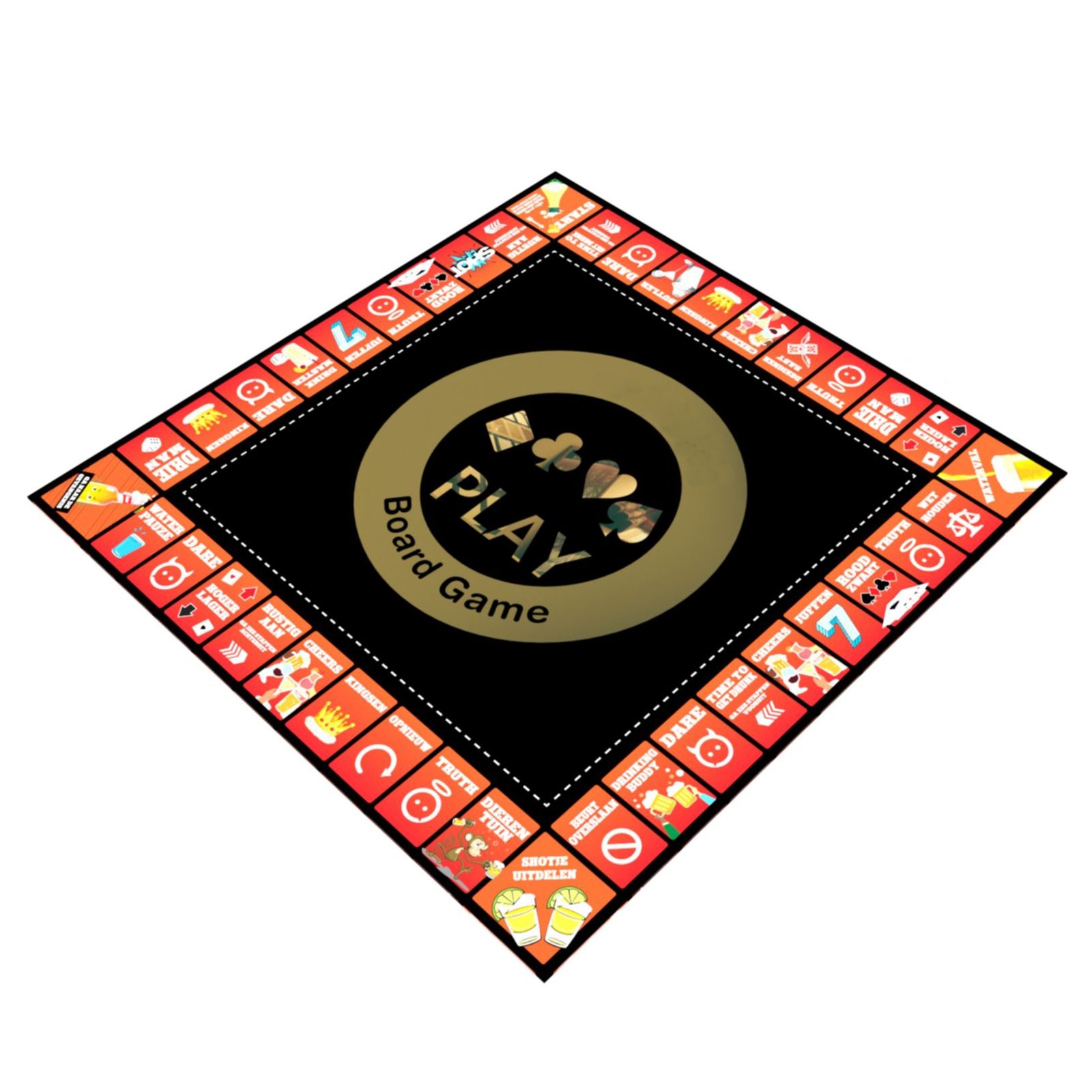

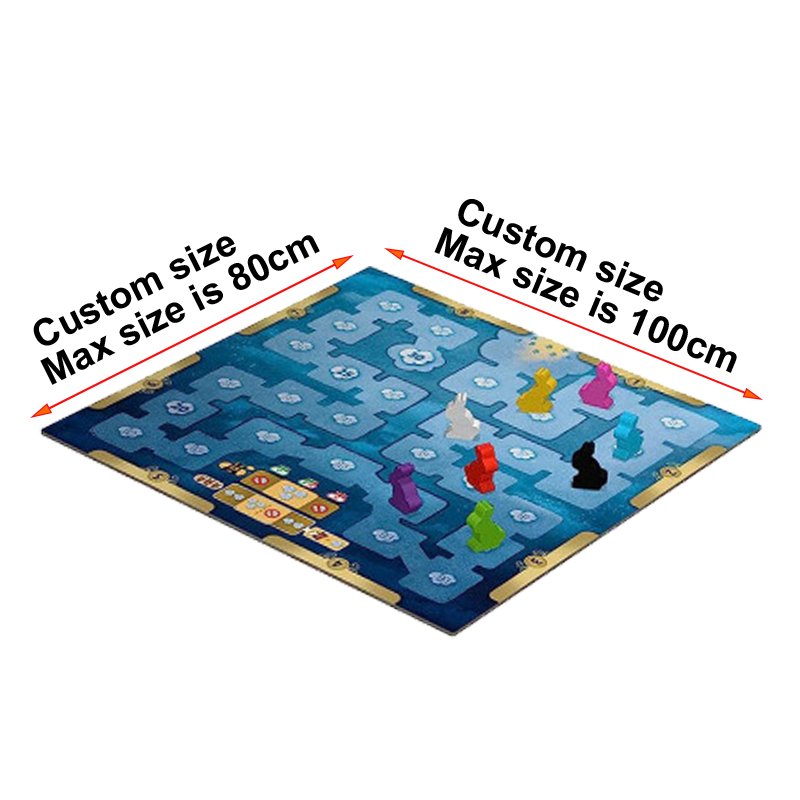

Custom Game Board Sizes

Standard & Custom Sizes

Whether you are designing a fast-paced card game or an immersive strategy epic, we can accommodate any scale. We manufacture everything from compact travel-sized boards to expansive 30″ x 30″ maps. If our standard dimensions don’t fit your vision, we provide full custom sizing or shape to create a unique footprint for your game world.

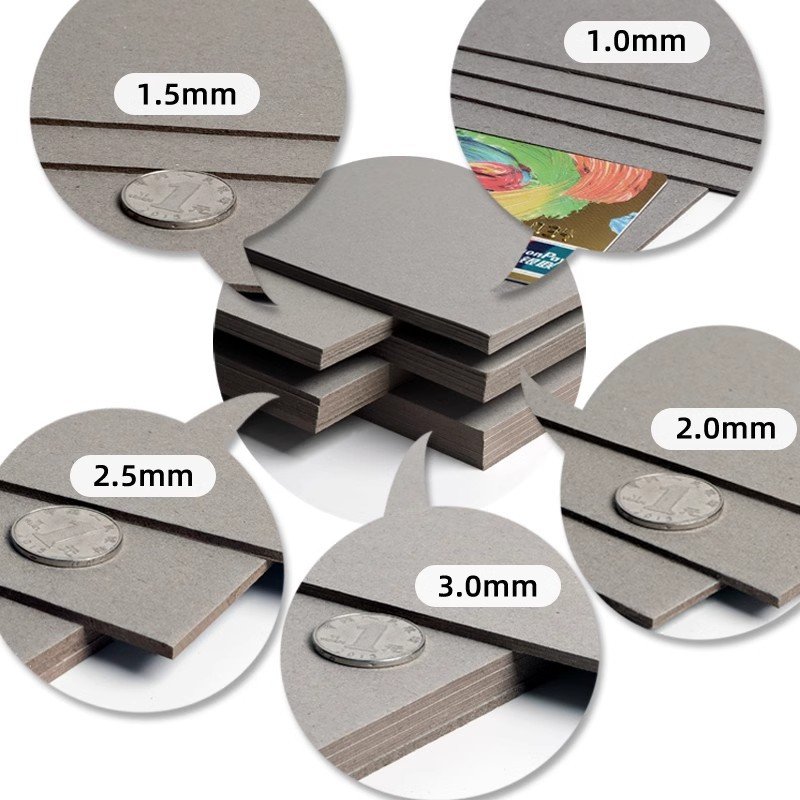

Thickness Options

The thickness of a board directly impacts the “table presence” and perceived value of your game. We offer four distinct thickness tiers to match your budget and quality requirements:

2.5mm – 3mm: The industry standard for “Deluxe” or “Collector’s Edition” titles, providing a substantial, professional heft.

1.5mm – 2mm: Ideal for lightweight or portable games.

Custom Game Board Folds

To ensure your game components fit perfectly inside your custom box, we offer a variety of precision-engineered folding options. Our specialized hinge-cutting technology allows for smooth, repeated folding without tearing or weakening the seams.

Classic Folding: Choose from Bi-fold, Tri-fold, Quad-fold or Six-fold designs.

Modular Boards: For games with evolving maps, we produce interlocking modular tiles and puzzle-cut boards with seamless edge matching.

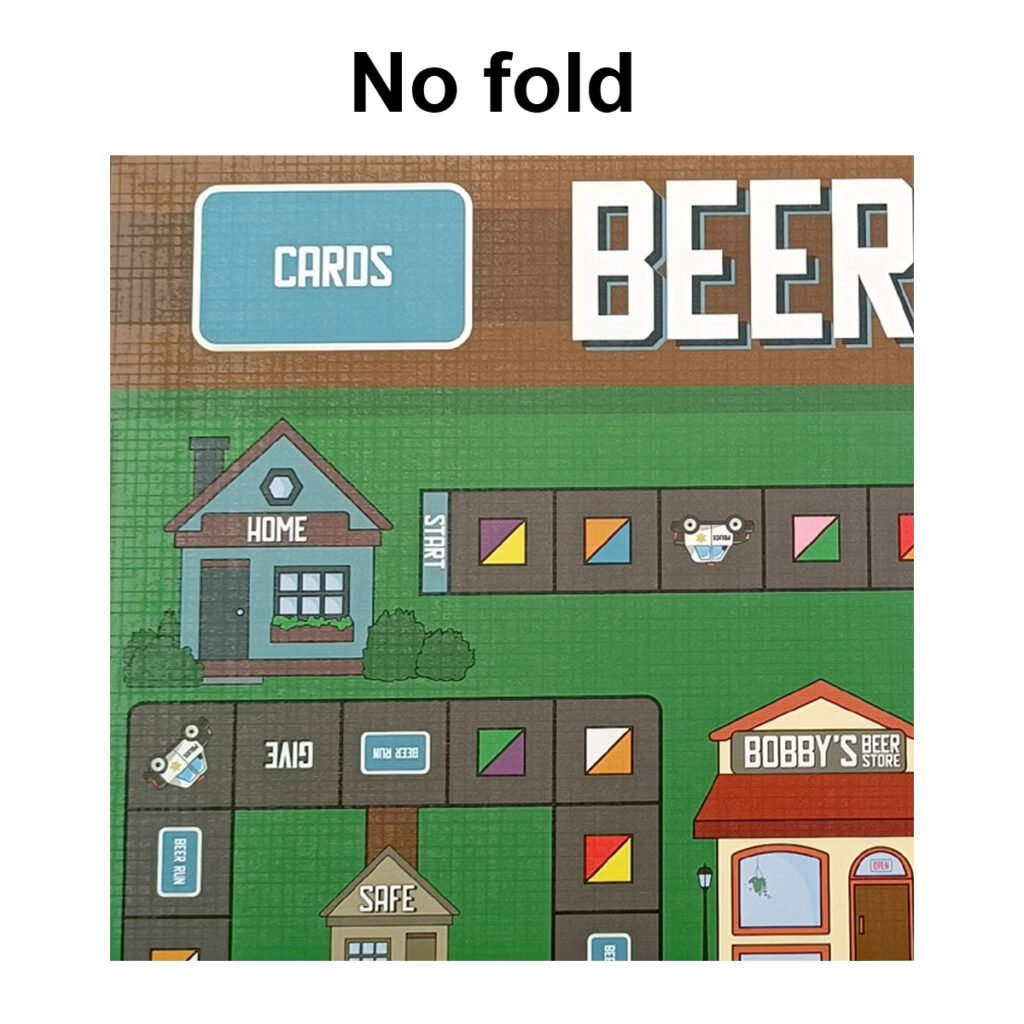

No-fold

This isn’t a fold at all, just a flat board that fits in the box as-is!

Bi-fold

Typically a single fold right down the symmetrical middle of a rectangular panel, splitting it into two parts. Basically, you fold the board in half.

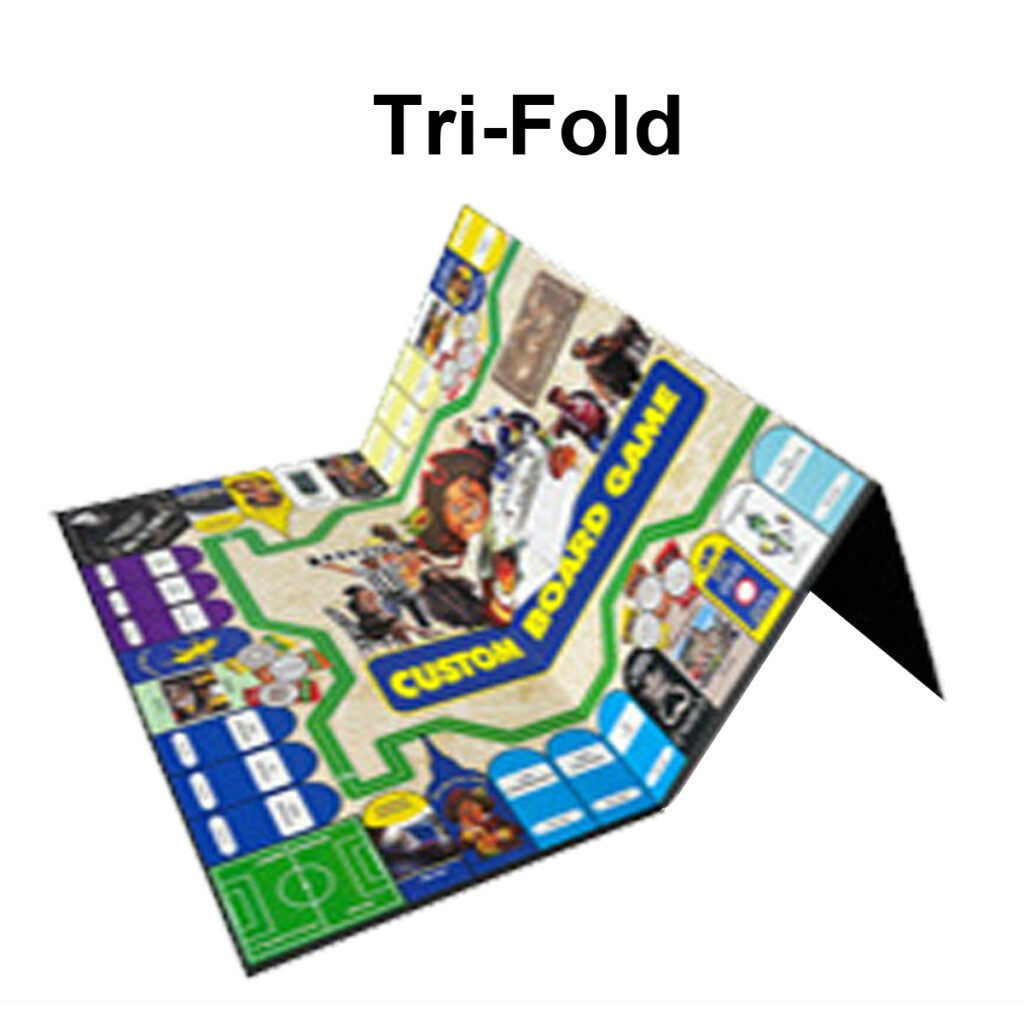

Tri-fold

This has two folds and folds up like a concertina with one of the outer panels folding back and the other forward over the middle panel.

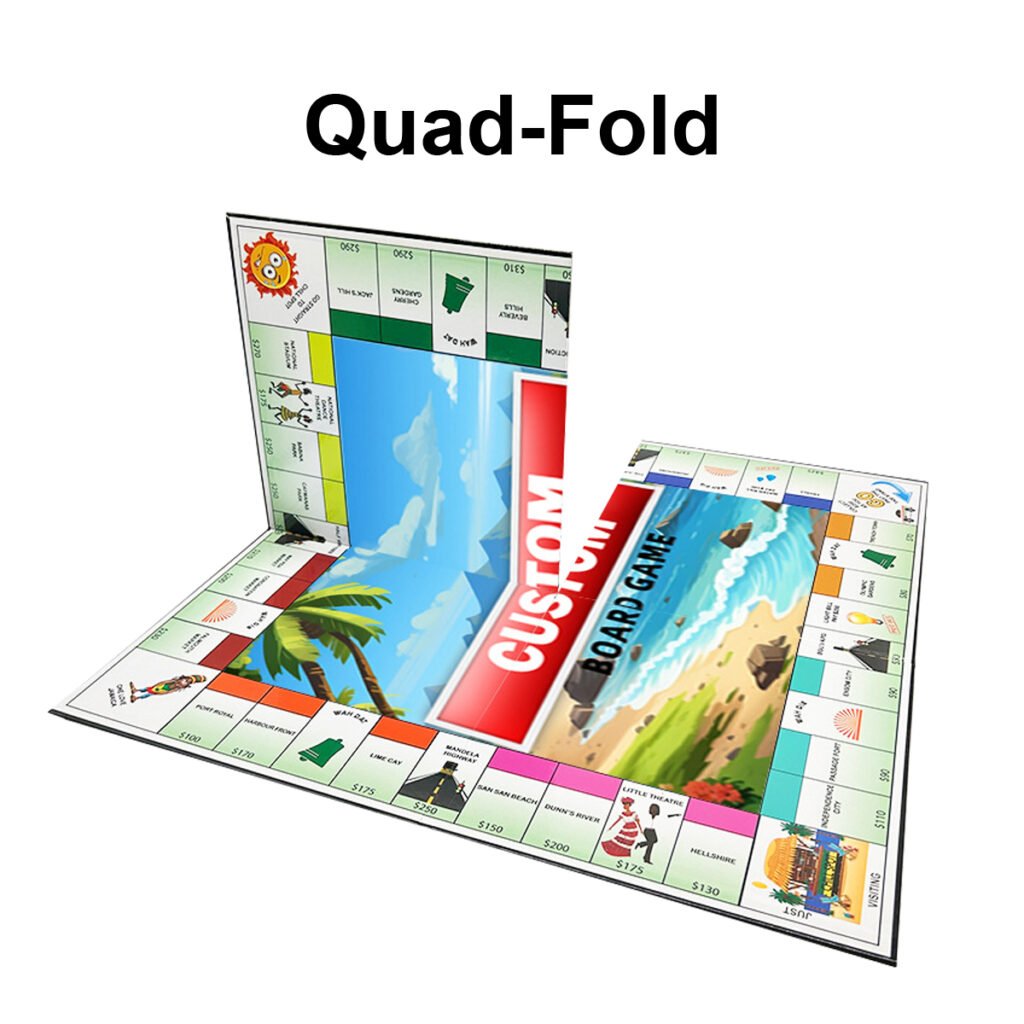

Quad-fold

This fold requires a cut to split a section of the board, so that the two upper quarters fold down over the two lower quarters and then the whole board folds back on itself.

Six-fold

This board is divided into six panels with three parallel folds. It folds up in a zigzag (accordion-style) to create a compact size.

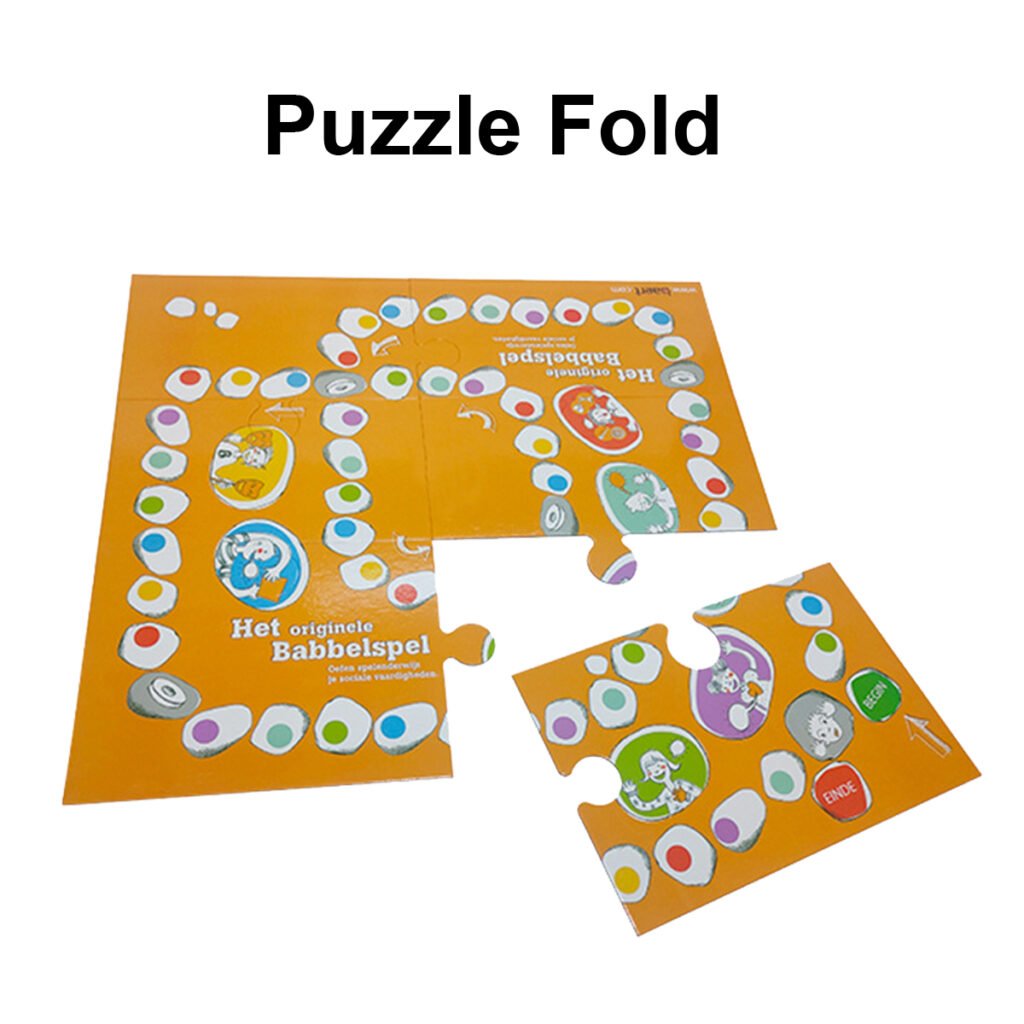

Puzzle-fold

The board is die-cut into multiple interlocking pieces instead of folding on hinges. The sections assemble like a puzzle to form the full play area, allowing compact storage and modular layouts.

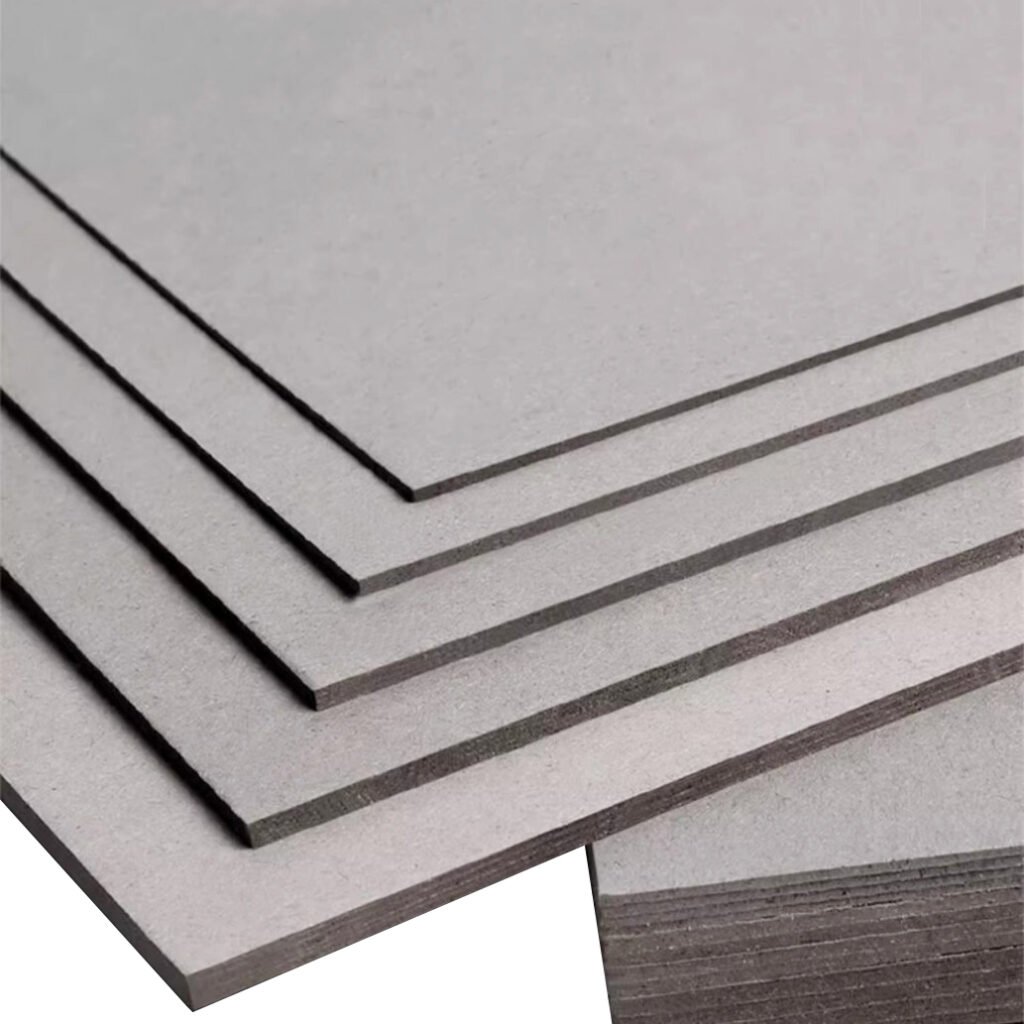

High-Density Core Materials

The longevity of a game board starts from within. We utilize industrial-grade high-density greyboard (also known as chipboard) as our primary core material. This ensures maximum structural rigidity and superior warp resistance, keeping your board perfectly flat even in varying humidity. By wrapping this sturdy core with premium litho paper, we achieve a solid, heavy feel that signifies high-end retail quality.

Custom Game Board Printing

Game board printing is engineered for color consistency, alignment accuracy, and long-term surface durability, not just visual impact. Our printing process is calibrated to ensure artwork remains stable across large-format boards and multi-panel folds.

Offset Printing for Large-Format Boards

All game boards are produced using high-resolution offset printing, optimized for large sheet sizes and complex folding layouts.

- Ensures consistent color reproduction across the entire board surface

- Maintains sharp line definition for grids, icons, and text

- Supports precise front-to-back registration for double-sided boards

Color profiles are standardized and calibrated per production run to prevent visible color shift between panels or across fold lines.

Where enhanced visual emphasis is required, gold or silver foil stamping and Spot UV finishing can be selectively applied as post-print processes to highlight key elements such as titles, regions, or focal artwork. These effects are engineered to align with board geometry and avoid stress points at folds, preserving long-term durability and flat-lay performance.

Custom Game Board Finishes

A great game board must withstand hundreds of play sessions. We offer professional-grade surface treatments to protect your artwork from moisture, oils, and wear.

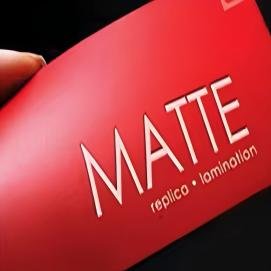

Soft Touch Lamination

Soft touch lamination is a premium specialty film engineered to deliver a distinct tactile experience. It cures to an ultra-matte, non-reflective surface with a velvety, suede-like feel that immediately communicates high perceived value.

This finish enhances color depth without gloss glare, making artwork appear richer and more controlled. While it provides effective protection against moisture and edge fraying, its soft surface requires careful handling, as it can be more sensitive to oils or deep scuffs compared to hard-coat laminations.

Engineering characteristics:

Ultra-matte, non-reflective surface

Distinctive soft-touch tactile response

Durable barrier with higher cosmetic sensitivity

Recommended for:

Deluxe editions, Kickstarter premium tiers, and boutique game releases.

Linen Finish (Embossed Texture)

Linen finish introduces a micro-embossed texture that mechanically reduces surface contact between cards.

Rather than relying solely on coatings, this texture improves airflow and separation during shuffling, especially in humid environments.

Engineering characteristics:

Improved shuffle separation

Reduced sticking

Requires specialized embossing rollers during the finishing stage

Recommended for:

Traditional playing cards and shuffle-intensive games.

Glossy Varnish

A glossy varnish is a clear, liquid coating applied to the printed surface, which is then typically air-dried or cured with UV light. Its primary function is to provide a protective layer that guards against scuffing, fingerprints, and minor abrasions. Visually, it significantly enhances the vibrancy and saturation of the underlying inks, making colours appear richer and more intense.

It creates a reflective, shiny surface that gives the paper a slick, polished look. This finish is often chosen for projects where a vibrant, eye-catching appearance is desired. However, its highly reflective nature can sometimes cause glare under bright lights, potentially affecting readability.

Matte Varnish

matte varnish, also a liquid coating, serves a similar protective purpose as its glossy counterpart but offers a completely different aesthetic and tactile experience. It dries to a non-reflective, velvety smooth finish that eliminates glare, making it an excellent choice for understated branding. It provides a sophisticated and premium feel that is often associated with high-end products.

While it protects against scuffs, the matte surface can sometimes be more susceptible to showing fingerprints or smudges compared to a gloss finish. It is particularly valued for its ability to enhance readability and provide a subtle, tactile depth to the design without altering the colour tones with added shine.

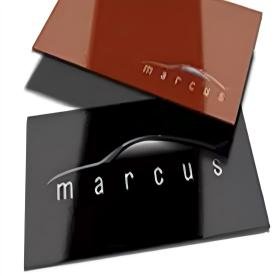

Glossy Lamination

Glossy lamination involves thermally bonding a thin, clear plastic film (usually polypropylene) to the entire surface of the printed sheet. This process creates an exceptionally durable and robust barrier that is highly resistant to water, moisture, tearing, and heavy abrasion. The gloss film intensifies colours to a degree similar to gloss varnish but with a more pronounced and physically resilient shine.

It is the go-to choice for items that require maximum durability and a high-impact visual finish. The film effectively seals and protects the printed piece, significantly extending its lifespan.

Matte Lamination

Matte lamination applies a non-glossy plastic film to the paper, offering the same superior level of physical protection as glossy lamination—including resistance to water, tearing, and scratches—but with a premium, tactile quality. The finish is smooth and silky to the touch, providing an exceptionally sophisticated look and feel that minimizes light reflection and glare.

It is highly effective at concealing fingerprints and minor surface imperfections. This makes matte lamination a preferred option for luxury cards, packaging and any application where a refined, understated elegance and durability are paramount.

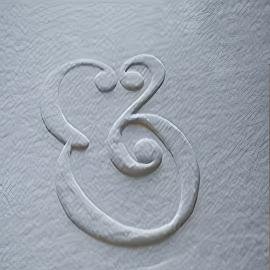

Embossing

Embossing is a finishing technique that uses a male and female die set to press the paper from both sides, creating a raised, three-dimensional design on the surface. This process does not involve adding ink or colour but relies on the play of light and shadow to highlight logos, patterns, or text. It adds a profound tactile dimension and a tangible sense of quality and depth to the printed material.

Embossing can be combined with other techniques like foil stamping or spot varnish to further accentuate the raised area, making it a powerful tool for creating emphasis and a memorable, luxurious sensory experience on items.

Debossing

Debossing is the opposite of embossing. It uses a similar die-stamping process, but instead of raising the paper, it presses the design down into the surface, creating a recessed impression. This technique impresses a permanent, indented mark that conveys a sense of permanence and craftsmanship. Like embossing, it is a tactile process that enhances the perceived value of the product through touch.

Debossing can be used on its own for a subtle, elegant effect, or it can be paired with a fill such as coloured foil or ink (a technique known as “blind debossing” when no colour is added).

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Engineering & Stability

Structural Engineering & Long-Term Board Stability

A premium game board is defined not by artwork alone, but by its ability to remain perfectly flat, aligned, and durable throughout years of gameplay and global shipping. Our board process is engineered from the core outward to eliminate warping, hinge fatigue, and edge failure.

Core Material Stability & Anti-Warping Control: We manufacture all boards using high-density, kiln-dried, neutral pH greyboard, which is selected for its dimensional stability and resistance to environmental humidity.

Moisture Conditioning: Greyboard is pre-conditioned to a stable moisture content of 6%–8%, aligning with international shipping and storage standards.

Symmetrical Lamination Engineering: Identical paper tension and adhesive volumes are applied to both sides of the board. This balanced lamination prevents internal stress that causes bowing or curling during curing.

Post-Production Seasoning: Finished boards undergo a controlled flattening and pressure-resting cycle to ensure absolute planarity before packaging. This process ensures boards remain flat even in fluctuating climates.

Precision Wrapping & Turned-Edge Craftsmanship

A board’s durability is often determined by its edges. We use automated high-precision wrapping systems to integrate surface art seamlessly with the core structure.

Tight Corner Tucking: Our turned-edge process wraps surface paper tightly around the greyboard with zero air gaps, preventing corner mushrooming or peeling.

Adhesive Chemistry Selection: We utilize flexible protein-based or synthetic adhesives that retain elasticity, ensuring hinges remain durable after thousands of folding cycles.

Texture Compatibility Calibration: Rollers are pressure-calibrated to accommodate smooth art paper or linen-textured wraps without fiber crushing or surface distortion.

Folding Alignment & Hinge Engineering

For multi-fold boards, hinge precision determines both visual continuity and table stability.

Registration Accuracy: Fold alignment is controlled within ±1mm tolerance, ensuring map grids and artwork align seamlessly when deployed.

V-Groove & Scored Hinges: Depending on board thickness (1.5mm–3.0mm), we apply precision V-cutting or reinforced scoring to create clean, lay-flat hinges.

Stress-Relief Geometry: Engineered clearance gaps at fold lines prevent surface paper stretching or tearing, eliminating spring-back and ensuring the board lies flat on the table.

Cost Drivers & MOQ Optimization

Core Thickness & Material Density

Greyboard thickness and density are the primary cost drivers. Thinner, lower-density cores reduce material usage and press time, making them suitable for lightweight or travel games. Thicker, high-density boards increase material consumption and processing time but deliver greater rigidity, flat-lay stability, and perceived value for premium releases.

Board Size & Folding Structure

Board dimensions and fold complexity directly impact material yield and labor input. Standard-sized bi-fold boards offer the highest production efficiency. Larger formats and multi-fold structures (quad-fold or six-fold) require additional scoring, hinge engineering, and alignment control, increasing unit cost.

Surface Finishing Effects

Surface protection and decorative finishes add both material and process cost. Varnish coatings are the most economical option. Laminations, soft-touch finishes, embossing, Spot UV, and foil stamping introduce additional production passes and tooling, and are typically specified for deluxe or collector editions.

Order Volume & Production Efficiency

Game board production benefits significantly from scale. Higher order volumes improve press utilization, reduce setup amortization, and lower per-unit labor cost. Smaller runs remain feasible but carry higher unit pricing due to fixed setup and tooling overhead. Early alignment between board specifications and realistic MOQ targets helps optimize both manufacturing efficiency and retail pricing strategy.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!