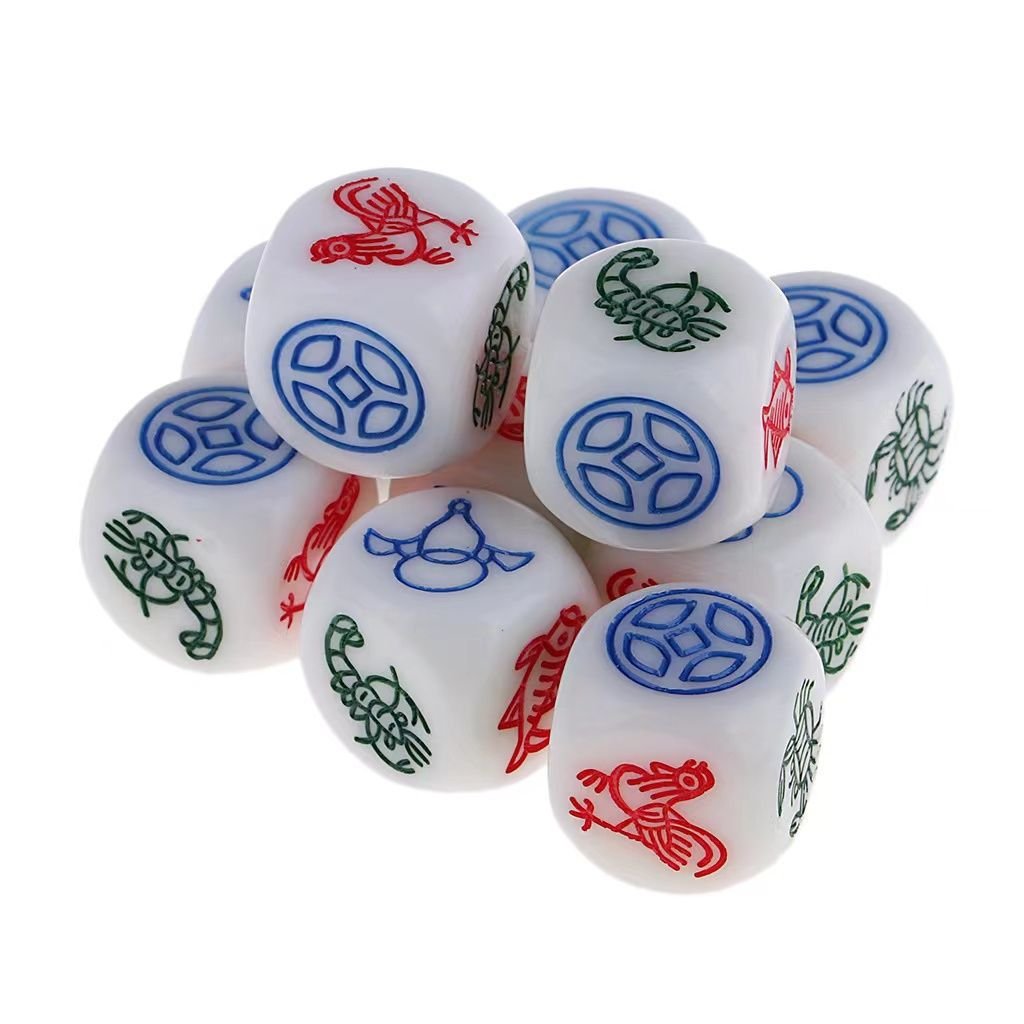

Precision-Engineered Dice

for Board Games & Tabletop Games

Dice are not decorative accessories—they are precision game components. Balance symmetry, dimensional accuracy, surface durability, and symbol clarity directly affect gameplay fairness and player trust.

At Funway, custom dice are manufactured through controlled molding, material engineering, and tolerance-driven process control to ensure consistent roll behavior across large production runs. Whether producing standard D6 sets, symbol-based custom dice, or collector editions, our dice are engineered for repeatability, durability, and retail-ready integration into board game production.

We Provide All options for Custom Game Boards

Dice Materials & Performance Characteristics

Material selection directly defines a die’s weight distribution, impact resistance, edge durability, and long-term roll consistency. We guide material selection based on gameplay frequency, tactile expectations, visual requirements, and cost control.

Injection-Molded Plastic Dice (The Industry Standard)

Best For: Core board game dice, standard D6 sets, and high-volume commercial production.

Injection-molded plastics remain the most reliable solution for gameplay-critical dice where repeatability, balance stability, and cost efficiency are required.

Engineering Focus: We prioritize density stability and controlled shrink behavior to ensure predictable roll outcomes across large production runs.

Material Options:

- ABS: Stable density, high impact resistance, strong edge durability

- Acrylic: Improved surface hardness and visual clarity for translucent designs

Key Properties:

- Stable mass distribution for consistent roll behavior

- Low shrink variation for dimensional repeatability

- Strong resistance to edge chipping under repeated rolling

Manufacturing Notes:

- Multi-cavity steel molds with symmetric cooling paths

- Gate positioning designed to avoid core voids and face density bias

- Suitable for long-run, high-cycle production

Resin Dice (Cast or Molded)

Best For: Boutique runs, collector editions, translucent or swirl-effect dice.

Resin allows greater visual flexibility and deeper symbol definition, making it suitable for limited editions where aesthetics are prioritized over volume efficiency.

Engineering Focus: Primary risk is density variation, which can affect balance if not properly controlled.

Key Properties:

- High visual depth and symbol fidelity

- Greater sensitivity to internal density inconsistency

Process Controls:

- Vacuum degassing and pressure casting during molding

- Batch-level weight sampling during First-Article Inspection (FAI)

Limitations:

- Not recommended for high-volume core gameplay dice due to variability risk

- Longer cycle times and higher labor input

Metal Dice (Zinc Alloy)

Best For: Premium editions, novelty dice, and collector-focused sets.

Metal dice provide significant weight and tactile impact, offering a distinct handling experience compared to plastic systems.

Engineering Focus: Mass-center alignment is critical to prevent roll bias caused by uneven material removal during finishing.

Key Properties:

High mass and pronounced tactile feedback

Increased roll momentum

Manufacturing Constraints:

Precision cavity balance during casting

Controlled polishing to avoid asymmetric material loss

Weight symmetry verification during FAI is mandatory

Wooden Dice

Best For: Family games, educational titles, and thematic or traditional designs.

Wooden dice offer a lightweight, organic alternative with a softer tactile response and strong thematic fit.

Engineering Focus: Wood grain orientation and moisture control are managed to reduce warping and dimensional drift.

Key Properties:

Lightweight with warm tactile feel

Natural surface variation by material type

Manufacturing Notes:

CNC shaping or die-cut block processing

Laser engraving or surface printing for symbols

Grain direction controlled to improve long-term stability

Dice Sizes, Shapes & Tolerance Standards

Dice geometry directly affects roll fairness and table behavior. We manufacture standard and custom profiles within defined tolerance limits.

Standard Dice Sizes

- 12 mm – Compact games and travel formats

- 14 mm – Industry standard for board games

- 16–18 mm – High-visibility or premium sets

Custom sizes are supported based on material system and mold feasibility.

Shape Variants

Standard D6 (Sharp-Edge Cubic): Provide higher surface friction and rapid roll termination, making them suitable for games requiring immediate result resolution and consistent tabletop behavior.

Rounded-Edge D6 (Tumbled): Engineered to reduce bounce noise and extend rolling travel. This profile improves hand ergonomics and reduces surface wear on printed game boards.

Polyhedral Dice Systems (D4–D20): Manufactured to standard RPG geometries, with specialized gate placement and cavity symmetry control to maintain balance across multi-face profiles.

Custom & Asymmetric Dice Profiles: Designed for non-standard mechanics or custom symbols. Each profile undergoes structural feasibility review to define mass-center alignment and production tolerances.

Dimensional Control

Edge length tolerance typically ±0.1 mm for injection-molded dice

Face flatness and corner geometry monitored to prevent roll bias

Consistency verified per cavity during sampling

Color Application, Symbols & Surface Finishing

Color, symbol treatment, and surface finishing directly affect readability, roll behavior, wear resistance, and production cost. Selection should balance visual clarity with expected roll frequency and gameplay requirements.

Color Methods:

Color methods are selected based on dice material system and visual requirements. Not all color effects are suitable for every material.

Solid-Color Injection

- Used for injection-molded plastic dice.

- Color pigments are compounded directly into the plastic material prior to molding, resulting in uniform color throughout the die.

- Trade-off: High durability and color consistency, with limited flexibility for post-mold color changes.

Translucent or Swirl Effects

- Applied primarily to resin dice and selected acrylic-based plastic dice.

- Trade-off: Strong visual differentiation with increased risk of density variation if not tightly controlled.

Multi-Color Overmolding (Project-Dependent)

- Used for plastic dice with layered color requirements.

- Trade-off: Improved visual contrast with higher tooling complexity and increased unit cost.

Symbol Application:

Symbol application methods are selected to ensure clarity, durability, and roll neutrality.

Mold-Engraved Symbols

Used for plastic and resin dice.

Provides the highest consistency across production runs. Engraving depth and layout are engineered to avoid measurable weight bias.

Laser Engraving (Post-Mold)

Applied to resin and acrylic dice for post-mold customization.

Trade-off: Permanent marking with limited depth control compared to mold engraving.

Pad Printing

Used across plastic, resin, and metal dice for high-contrast numerals or icons.

Trade-off: Strong visual contrast with wear considerations under heavy roll frequency.

Surface Finishes:

Surface finish selection affects roll feel, glare control, and long-term wear.

Gloss Polish

Applied to plastic, resin, and metal dice.

Trade-off: Smooth roll behavior and classic appearance, with higher glare under direct lighting.

Matte or Satin Finish

Used for plastic and resin dice where glare reduction is required.

Trade-off: Improved readability with slightly increased surface friction.

Frosted or Light Texture Finish

Applied selectively to plastic and resin dice.

Trade-off: Enhanced grip and reduced roll travel, with additional processing steps and cost.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Mold Engineering & Balance Control

Dice fairness is engineered, not assumed: Equal mass distribution across all faces is critical to predictable roll outcomes. Mold cavities are designed with geometric symmetry, optimized flow paths, and balanced cooling cycles to prevent internal voids or density gradients that could shift the die’s center of gravity.

For resin and metal dice: Weight and balance checks are conducted during FAI, with sample roll testing performed to verify neutrality within board-game standards. Material density variation can shift the center of gravity and affect roll outcomes.

Casino-grade statistical balance testing is not implied unless explicitly specified.

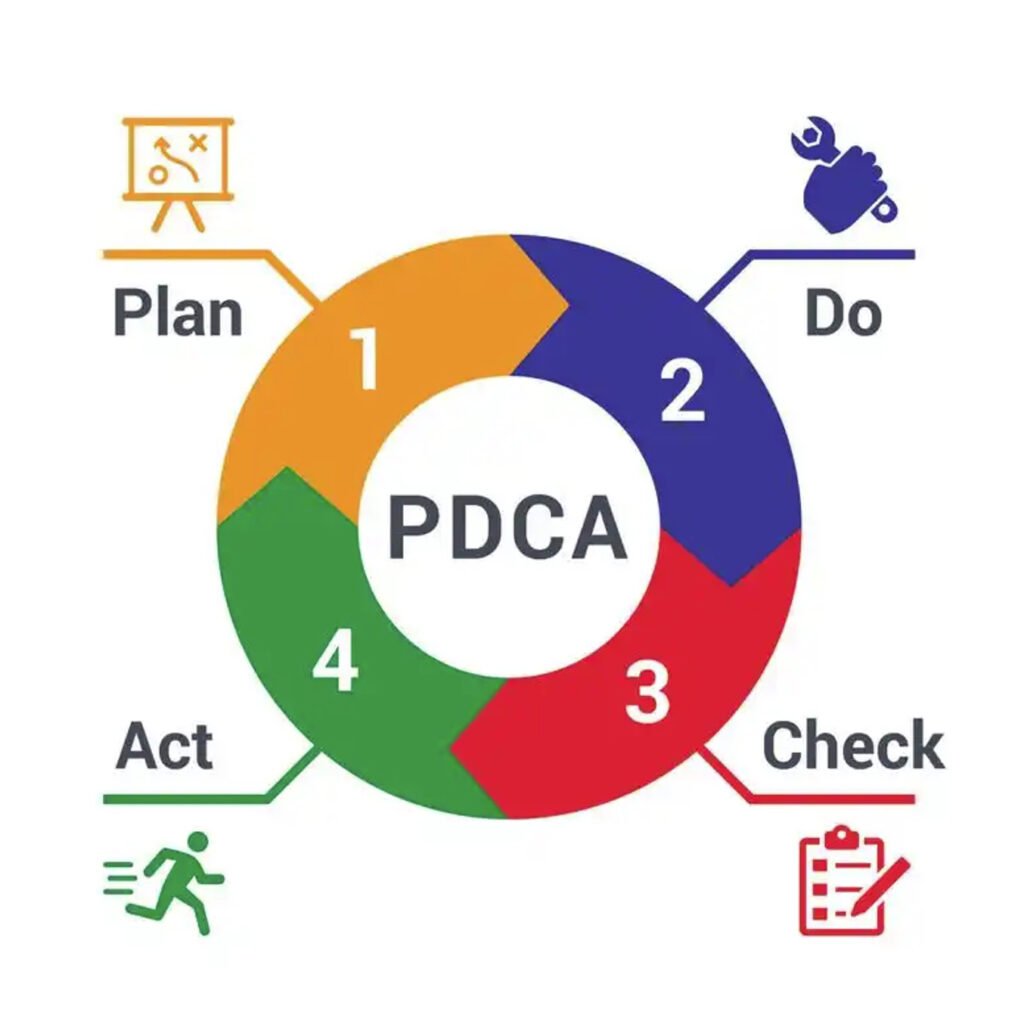

Prototyping & First-Article Inspection (FAI)

Before mass production, physical prototypes are produced for validation of:

- Size and dimensional accuracy

- Weight and balance behavior

- Color consistency

- Symbol clarity and alignment

- Approved FAI samples become the Golden Sample reference for full production.

Mass Production & Quality Control

- Dice are controlled through process monitoring, not post-production sorting.

- Injection parameter logging per batch

- In-process dimensional checks

- Visual inspection for surface defects and symbol fill

- Random roll sampling for functional verification

- All materials comply with EN71 and ASTM F963 requirements where applicable.

Cost Drivers & MOQ Optimization

Unit cost for custom dice is determined by a small set of controllable variables.

Material Selection:

Plastic is the most cost-efficient option

Resin and metal increase material cost and labor input

Dice Size & Geometry:

Larger sizes and non-standard shapes increase material usage and tooling complexity

Symbol Complexity & Color Count:

Multi-color symbols or deep engravings add processing steps

Order Volume (MOQ Optimization):

Injection-molded dice typically start from 5,000–10,000 units per design

For smaller projects, standard stock molds can be used to reduce tooling requirements, allowing lower MOQs while supporting limited customization in color and symbol layout

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!