Custom Board Game Box

for Board Games & Tabletop Games

The box is the first thing a player touches and the final layer of protection for your components. At Funway, we specialize in high-durability, professional-grade custom board game boxes that balance shelf appeal with structural integrity. From standard telescope boxes to premium magnetic closures, we manufacture packaging that meets global retail standards. All of our boxes can be treated with special finishes in order to make them stand out well, such as with spot UV, linen texture, foil stamping, and embossing.

We Provide All options for Custom Board Game Box

Industry-Standard Box Styles

Every game has a unique footprint. We offer a variety of structural designs to accommodate cards, boards, miniatures, and rulebooks.

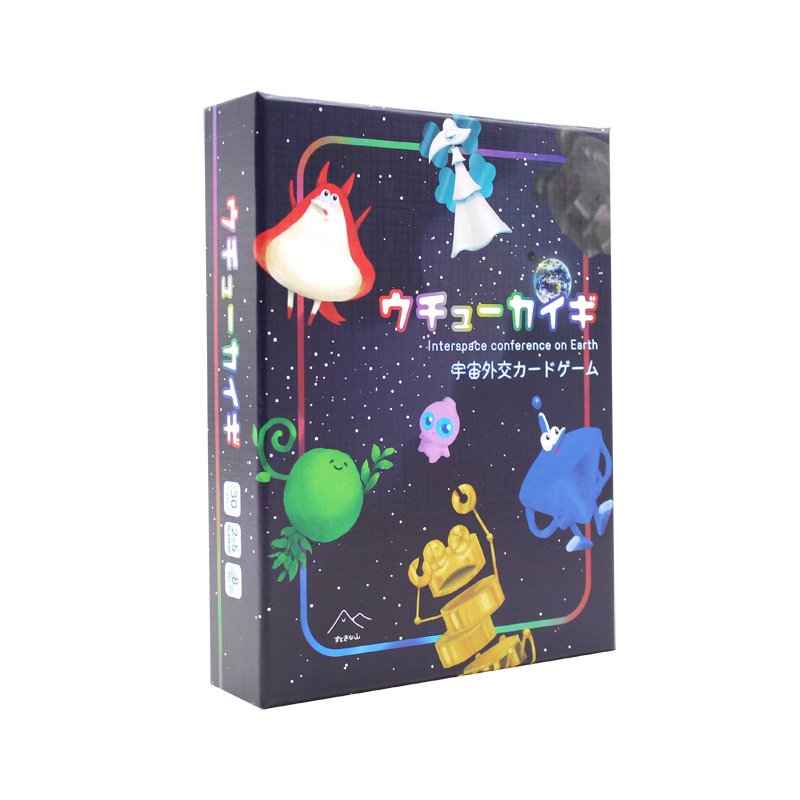

Two-Piece Telescope Boxes (Lid-and-Base Boxes) for Board Games

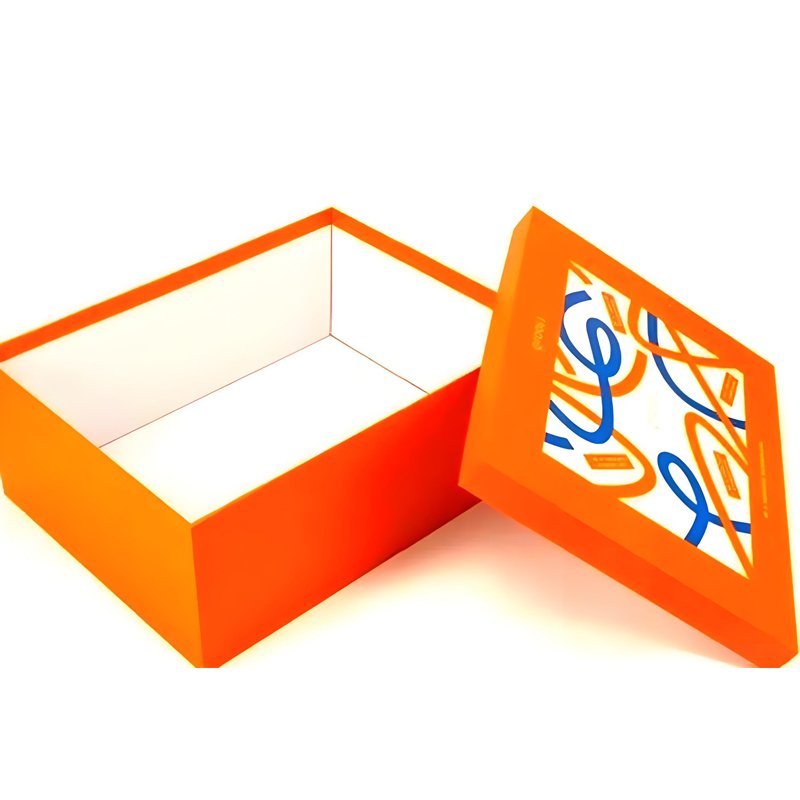

Two-piece telescope boxes, also known as lid-and-base boxes, are one of the most widely used box structures in the tabletop industry due to their strength, rigidity, and design flexibility. This box style is commonly chosen for strategy board games and legacy games that require long-term durability and stable internal support.

Our two-piece telescope boxes are manufactured using high-density greyboard cores, allowing the lid to fit with precise friction—secure enough for transport, yet smooth to open during gameplay. This construction helps maintain box shape even after repeated handling.

The lid-and-base structure also provides a large surface area for box art and sufficient vertical depth to accommodate multi-layered inserts, thick game boards, rulebooks, and miniatures. For complex board games with multiple components, telescope boxes remain the industry standard.

Tuck End & Hang Tab Boxes for Board Games & Card Games

Tuck end boxes are widely used for card games, game expansions, and compact travel games due to their lightweight structure and efficient material usage. For retail environments, hang tab boxes allow card games to be displayed on peg hooks, making them suitable for both hobby stores and mass-market retailers.

Our custom tuck boxes are manufactured using high-caliber C1S or C2S art board and precision-creased to withstand repeated opening and closing without structural failure. Both standard tuck end and hang tab box formats are available, allowing publishers to choose between shelf placement and peg-hook display based on their retail strategy.

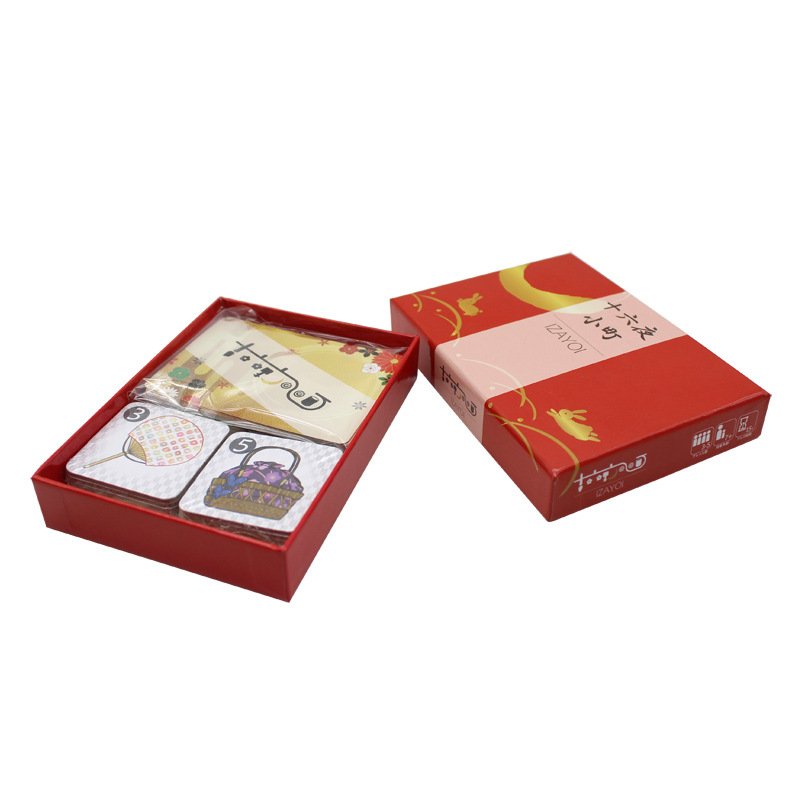

Magnetic Flip-Top Boxes for Board Games & Collector’s Editions

For board game publishers and Kickstarter creators, magnetic flip-top boxes are commonly used for Collector’s Editions, Deluxe tiers, and limited-edition releases where packaging quality directly affects perceived value.

Our magnetic flip-top boxes are manufactured with hidden high-strength magnets embedded inside the front flap. This magnetic closure design keeps the exterior clean while ensuring consistent alignment and a secure close during storage and transport.

The boxes use a one-piece wraparound structure, which provides higher rigidity than standard tuck boxes or two-piece lid-and-base boxes. This structure performs reliably during international shipping and maintains its shape after repeated opening and closing by players.

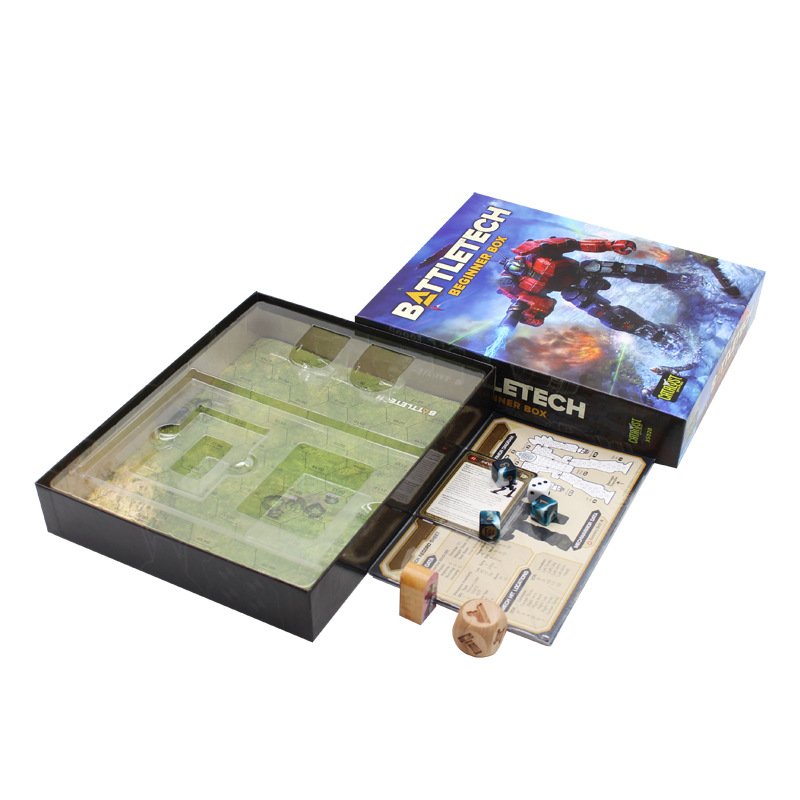

Drawer (Slide) Boxes for Card Games & Premium Decks

Drawer boxes, also known as slide boxes or matchbox-style boxes, feature a lateral sliding structure where an inner tray is enclosed by an outer sleeve. This construction reinforces the tray on all sides, resulting in a sturdy box structure that maintains alignment during repeated use.

Our drawer-style boxes are manufactured with precision die-cutting to ensure a smooth, controlled slide with minimal resistance. The fit between the sleeve and inner tray is carefully calibrated to prevent loosening while still allowing easy access to components.

This box style is commonly used for premium tarot decks, minimalist indie games, and card games that benefit from a clean, slide-out presentation of components.

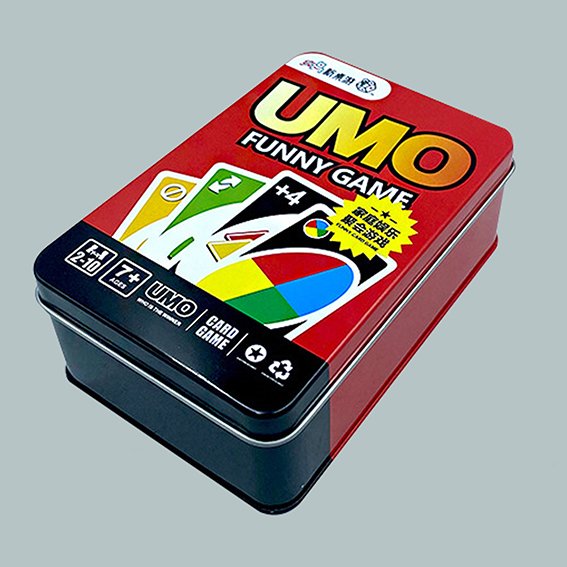

Tin Boxes (Metal Packaging) for special edition board games

Custom tin boxes are commonly used for special edition board games, premium card games, and travel-sized titles that require higher protection and long-term durability. Made from food-grade tinplate, these metal boxes provide strong resistance against drops and compression during shipping, while remaining compact and easy to carry.

We apply high-resolution offset printing directly onto the tin surface, with two finish options available: a gloss varnish for bold, vibrant artwork, or a matte coating that helps reduce fingerprints and surface wear during regular handling.

Tin boxes are frequently selected for luxury dice sets and collector’s card games, offering both durability and a classic appearance that works well for retail display and long-term storage. As fully recyclable packaging, they can also be reused by players to store game components, making them a practical choice for indie publishers and Kickstarter special editions. Custom embossing and logo printing are available for limited-run and collector-focused projects.

Engineering & Material Excellence: Built for Durability and Precision

At Funway, we go beyond surface-level printing. Our packaging is engineered to withstand long-haul international fulfillment and remain structurally stable after years of use on a collector’s shelf. Every box is built with a focus on material performance, structural behavior, and real-world handling conditions.

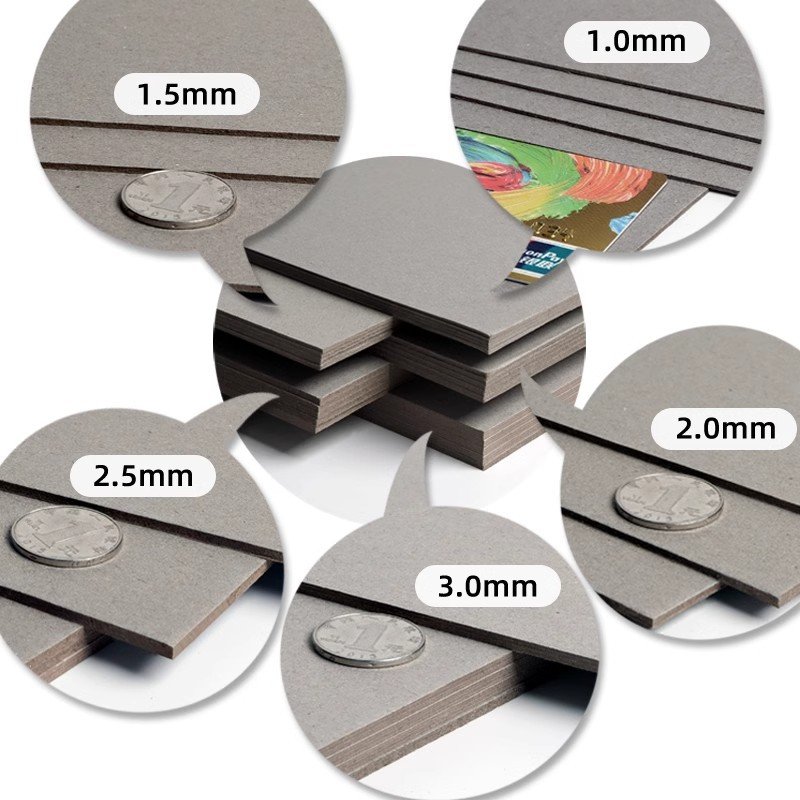

Reinforced High-Density Greyboard Core

The foundation of a premium game box lies in its structural rigidity. We exclusively use high-density chipboard, ranging from 1.5mm to industrial-grade 3.0mm, selected based on box size, weight load, and shipping distance to deliver reliable burst strength and impact resistance.

Warp Resistance: Our boards are conditioned and processed to maintain a flat profile, effectively preventing “dishing” (lid bowing)—a common failure point during long-duration ocean freight where humidity levels fluctuate significantly.

Reinforced Corners: By controlling the fiber direction and grain alignment of the greyboard during cutting, we improve corner strength at stress points. This significantly reduces the risk of corner splitting caused by drops, stacking pressure, and conveyor handling during fulfillment.

This is one of the most frequent failure modes we see in rigid boxes—and one we design specifically to avoid.

Premium Interior Linings & Esthetics

The interior of the box is just as critical for the player’s unboxing experience. We move beyond the raw, industrial look of unfinished greyboard to offer high-end interior solutions:

White-Lined & Custom Interiors: We provide white-lined interiors as a standard for a clean, medical-grade finish, or full-color interior printing to extend your game’s thematic artwork into the inner base.

Aesthetic Cohesion: This process eliminates the “dusty” texture of raw chipboard, ensuring that your cards, rulebooks, and specialized inserts remain in a pristine environment free from cardboard debris.

Finishes for Shelf Presence

In a crowded retail aisle or when fulfilling large Kickstarter campaigns, packaging must do more than contain game components—it needs to perform as a finished product throughout shipping, display, and repeated handling. We select surface finishes not only for visual impact, but for how they interact with lighting, touch, and long-term shelf exposure under real-world use.

By combining tactile coatings, controlled gloss levels, and targeted accents such as foil stamping or spot UV, we help elevate standard packaging into collector-grade editions. These treatments are commonly specified for deluxe and limited runs where visual differentiation, backer perception, and retail presentation directly influence purchasing decisions.

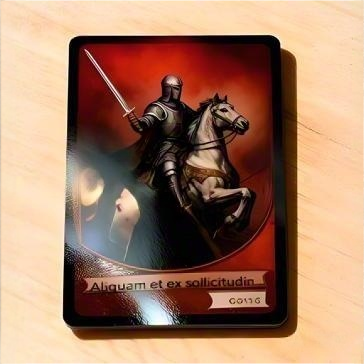

Spot UV Coating (Localized High-Gloss Polymer Layer)

Spot UV Coating applies a clear, high-gloss polymer selectively to designated artwork areas using UV-cured precision masking. This creates a sharp contrast between raised, reflective elements and the surrounding matte or soft-touch surface, enhancing visual hierarchy without altering the base print colors.

Unlike full-surface coatings, Spot UV is engineered purely for localized emphasis, allowing logos, icons, or key illustrations to visually “lift” from the card or box surface while maintaining a controlled overall finish.

Engineering characteristics:

UV-cured liquid polymer applied through precision spot masks

Creates a raised gloss layer without additional ink thickness

Requires accurate registration alignment with underlying artwork

Recommended for:

Logos, focal symbols, character illustrations, and dark-background designs where controlled gloss contrast adds depth without the cost of foil tooling.

Foil Stamping (Hot Foil Transfer)

Foil Stamping is a heat-and-pressure transfer process that bonds metallic or pigmented foil directly onto the substrate using a custom-etched metal die. Unlike metallic inks, foil produces a true reflective surface with mirror-like brilliance, independent of lighting angle or print density. Standard options include gold, silver, and holographic foils.

The stamping process slightly compresses the substrate, creating a subtle recessed profile that reinforces the visual authority of titles, logos, or premium markings. Because foil is applied as a solid layer, color consistency and reflectivity remain stable across long production runs.

Engineering characteristics:

Heat-activated foil transfer using hardened metal dies

Produces crisp edges and consistent reflectivity

Requires artwork optimization to maintain fine-line clarity

Recommended for:

Collector’s Editions, deluxe tiers, and premium branding elements where maximum visual contrast and shelf impact are required.

Glossy Varnish

A glossy varnish is a clear, liquid coating applied to the printed surface, which is then typically air-dried or cured with UV light. Its primary function is to provide a protective layer that guards against scuffing, fingerprints, and minor abrasions. Visually, it significantly enhances the vibrancy and saturation of the underlying inks, making colours appear richer and more intense.

It creates a reflective, shiny surface that gives the paper a slick, polished look. This finish is often chosen for projects where a vibrant, eye-catching appearance is desired. However, its highly reflective nature can sometimes cause glare under bright lights, potentially affecting readability.

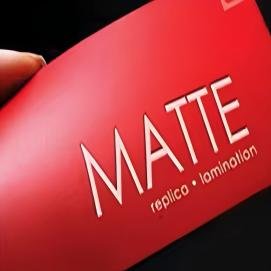

Matte Varnish

matte varnish, also a liquid coating, serves a similar protective purpose as its glossy counterpart but offers a completely different aesthetic and tactile experience. It dries to a non-reflective, velvety smooth finish that eliminates glare, making it an excellent choice for understated branding. It provides a sophisticated and premium feel that is often associated with high-end products.

While it protects against scuffs, the matte surface can sometimes be more susceptible to showing fingerprints or smudges compared to a gloss finish. It is particularly valued for its ability to enhance readability and provide a subtle, tactile depth to the design without altering the colour tones with added shine.

Glossy Lamination

Glossy lamination involves thermally bonding a thin, clear plastic film (usually polypropylene) to the entire surface of the printed sheet. This process creates an exceptionally durable and robust barrier that is highly resistant to water, moisture, tearing, and heavy abrasion. The gloss film intensifies colours to a degree similar to gloss varnish but with a more pronounced and physically resilient shine.

It is the go-to choice for items that require maximum durability and a high-impact visual finish. The film effectively seals and protects the printed piece, significantly extending its lifespan.

Matte Lamination

Matte lamination applies a non-glossy plastic film to the paper, offering the same superior level of physical protection as glossy lamination—including resistance to water, tearing, and scratches—but with a premium, tactile quality. The finish is smooth and silky to the touch, providing an exceptionally sophisticated look and feel that minimizes light reflection and glare.

It is highly effective at concealing fingerprints and minor surface imperfections. This makes matte lamination a preferred option for luxury cards, packaging and any application where a refined, understated elegance and durability are paramount.

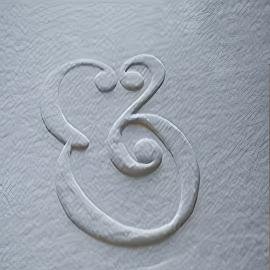

Embossing

Embossing is a finishing technique that uses a male and female die set to press the paper from both sides, creating a raised, three-dimensional design on the surface. This process does not involve adding ink or colour but relies on the play of light and shadow to highlight logos, patterns, or text. It adds a profound tactile dimension and a tangible sense of quality and depth to the printed material.

Embossing can be combined with other techniques like foil stamping or spot varnish to further accentuate the raised area, making it a powerful tool for creating emphasis and a memorable, luxurious sensory experience on items.

Debossing

Debossing is the opposite of embossing. It uses a similar die-stamping process, but instead of raising the paper, it presses the design down into the surface, creating a recessed impression. This technique impresses a permanent, indented mark that conveys a sense of permanence and craftsmanship. Like embossing, it is a tactile process that enhances the perceived value of the product through touch.

Debossing can be used on its own for a subtle, elegant effect, or it can be paired with a fill such as coloured foil or ink (a technique known as “blind debossing” when no colour is added).

Game Inserts: Engineered for Fit, Protection, and Longevity

A game box can only perform as well as the insert inside it. For crowdfunded and globally shipped games, the insert is a functional component engineered to manage weight, movement, and repeated handling—not just a visual divider.

Our custom inserts are designed around two measurable requirements: secure containment and efficient setup. Whether produced in molded pulp for sustainability or vacuum-formed plastic for high-precision component control, each layout is calibrated to prevent component shift during international transit. Card wells, miniature cavities, and token compartments are dimensioned to minimize surface abrasion and impact stress, ensuring components remain protected from fulfillment through long-term gameplay.

Paperboard Insert

Paperboard inserts, precision-folded from high-caliber art card or corrugated stock, are the standard choice for professional board game organization. These inserts are custom-engineered to create dedicated compartments for cards, tokens, and boards while maintaining the structural integrity of the outer box. Dries to a clean, geometric finish, they offer a highly customizable surface that can be left white or printed with full-color artwork to extend the game’s theme into the interior.

While they offer an eco-friendly and cost-effective solution for securing components, paperboard structures are best suited for lighter items and may require strategic folding to prevent movement during heavy transit. They are particularly valued for their sustainable profile and the ability to be shipped flat, reducing carbon footprint. For Indie Publishers, paperboard inserts provide a professional “retail look” without the high tooling costs associated with plastic alternatives.

Blister Insert (Vacuum Formed Tray)

Blister inserts, produced through precision vacuum forming of PVC or PET sheets, are commonly specified for games with a high volume of small or detailed components. Each tray is custom-molded to match the exact geometry of miniatures, dice, and card stacks, creating a secure, snap-fit layout that prevents component movement regardless of box orientation during shipping.

The vacuum-formed structure provides excellent spill resistance and component separation, though it requires a one-time tooling investment for aluminum molds. This insert type is frequently used in miniature-heavy strategy games and Collector’s Editions where minimizing surface friction and paint wear between figures is critical. PET-based options are also available for publishers seeking a recyclable material without sacrificing dimensional precision.

Molded Pulp Tray

Molded pulp trays are formed from recycled paper fibers using a wet-pressing process that creates a rigid, impact-absorbing structure. The resulting tray has a natural matte surface and a dense fiber profile that performs well under compression and drop stress during shipping.

This insert type is commonly specified for publishers prioritizing plastic-free packaging and overall shock protection. Due to the organic fiber structure, dimensional tolerances are broader than vacuum-formed plastic, making molded pulp better suited for larger components such as decks, boards, or bagged tokens rather than tightly fitting miniatures. For eco-focused projects, molded pulp offers a durable and fully biodegradable alternative that aligns sustainability goals with functional protection.

Foam Inserts (EVA or PE Foam)

Foam inserts, cut using CNC routing or laser die processes, are specified for projects that require maximum shock absorption and component immobilization. High-density EVA or PE foam is used to create form-fitting cavities that support fragile resin miniatures, glass components, or oversized tokens during long-distance shipping.

Due to the material thickness required for effective protection, foam inserts occupy more internal volume and carry a higher unit cost than paperboard or molded pulp alternatives. They are most commonly used for Kickstarter all-in tiers and luxury editions where component protection outweighs space efficiency. The closed-cell foam surface minimizes abrasion and surface contact, making it suitable for high-value components that are sensitive to impact or scratching.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Professional Manufacturing Standards for Global Tabletop Brands

At Funway, we recognize that a game box is a structural asset, not just a marketing tool. Our manufacturing facility operates under the rigorous quality demands of the global tabletop industry, ensuring every box we produce meets the expectations of collectors, retailers, and international distributors.

As a specialized board game manufacturer, our process is defined by three core pillars of professional integrity:

Structural Precision

We utilize advanced high-speed automated wrapping lines that ensure the outer litho-wrap is applied with consistent tension. This eliminates common manufacturing defects such as air bubbling, corner tearing, or uneven seams—ensuring a clean, “snug” fit between the lid and base every time.

Material Integrity (FSC-Certified Options)

We prioritize the use of high-density, virgin-fiber greyboard. Unlike recycled materials of inferior quality, our boards offer superior burst strength and warp resistance, meaning your game arrives at the player’s door in the same condition it left the factory.

Color Consistency & Calibration

Using color management and high-precision offset printing, we ensure that your brand’s palette remains consistent across multiple print runs. Whether it is a base game or a future expansion, we maintain strict Delta-E tolerances to prevent color drifting.

From the initial structural dummy (white sample) to the final mass production, we act as your technical partner. We don’t just follow specifications—we audit them to ensure your box is engineered for the weight of your components and the rigors of global fulfillment.

Standardized audits for every production run.

Built for Kickstarter Fulfillment & Global Shipping

Crowdfunded board games face very different stresses than traditional retail products—particularly after components are punched, sorted, and repacked for fulfillment. Our box structures are engineered with these real-world conditions in mind, not just factory drop tests.

Burst Strength

Designed to support high component loads such as metal coins, resin miniatures, and multi-layer inserts without panel splitting or corner failure during pallet stacking.

Lid Fit & Lift Calibration

Lid tolerances are calculated to account for post-production changes, ensuring the box still closes flush after cards are sleeved and components are bagged—avoiding the common “lid float” issue seen in crowdfunded games.

Shipping & Last-Mile Durability

Engineered to withstand repeated handling from fulfillment centers through last-mile delivery, reducing corner crush and edge wear upon arrival at backers’ doorsteps.

Cost Drivers & MOQ Optimization

At Funway, custom game boxes are treated as structural packaging components rather than decorative containers. Box size, construction method, and board specification directly influence insert design, component packing, and shipping configuration, placing box specification on the critical path of board game production. Early definition of box structure and dimensions helps stabilize tooling decisions, production scheduling, and downstream manufacturing steps.

Box Structure & Construction Method

Different box structures require different levels of material input and assembly complexity.

Folding cartons and tuck-end boxes rely on single-piece die cutting and automated folding

Rigid boxes, telescope boxes, and magnetic-closure designs require additional board material, lamination steps, and manual assembly

Box structure selection directly affects tooling complexity, labor input, and production cycle time.

Box Size, Board Thickness & Load Requirement

Box dimensions and board thickness determine material usage and stacking strength.

Thicker greyboard increases crush resistance and long-term stacking stability

Larger box formats increase material consumption and reduce pallet density

Board specification is typically defined based on component weight, stacking height, and shipping conditions.

Printing Coverage & Surface Finishing

Artwork coverage and surface treatment affect press setup, ink usage, and downstream processing.

Full-coverage artwork and dark saturation increase ink consumption and drying time

Lamination and protective coatings add additional processing steps

Specialty finishes introduce separate setup and handling stages

Printing and finishing choices should be finalized before tooling release to avoid rework.

Insert Integration & Fit Precision

Game boxes designed to integrate tightly with inserts require tighter dimensional control during die cutting and assembly.

Precision fit increases tooling accuracy requirements

Dimensional variation directly affects insert compatibility and packing efficiency

Box and insert specifications are reviewed together during pre-production to maintain fit consistency.

Order Volume & MOQ Considerations

MOQ for custom game boxes is primarily determined by printing efficiency and die-cut tooling amortization.

Press setup and die-cut tooling costs are distributed across the production volume

Lower volumes carry higher setup cost per unit

For smaller production runs, standard box styles or shared die-cut toolings can be used to reduce MOQ while maintaining custom artwork and branding.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!