We Provide All options for Custom Cards

As an advanced Cards Manufacturer, FUMWAY can provide 100% customization for your Program.

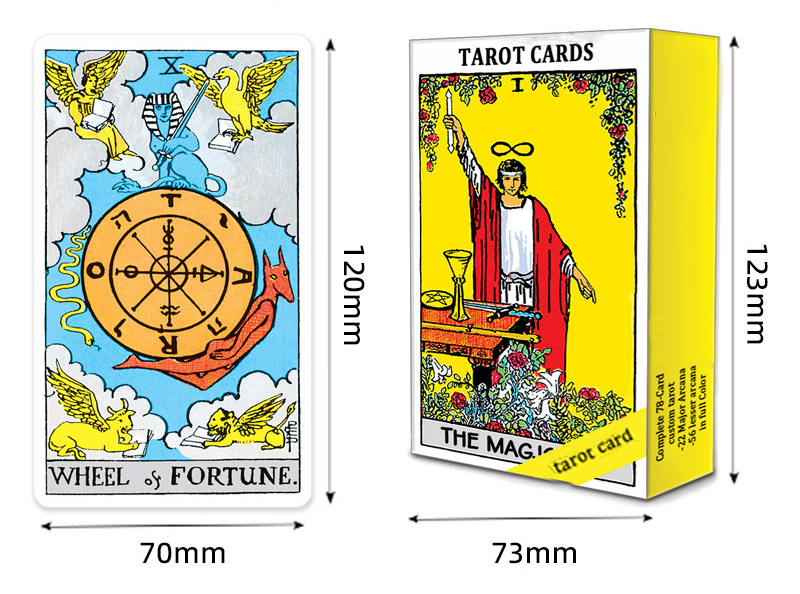

Funway offers 5 common sizes for both playing cards, tarot cards, flash cards, drink cards and game cards. You can select these common size to create customized cards (with your own designs, logos, patterns, colors, and surface finishing) in a cost-effective and streamlined way. If our current standard sizes do not fit your needs, we can develop a custom-sized die-cut mold specifically to your requirements. Bring your product vision to life with attention-grabbing graphics, material, printing, surface finishings, and personalized branding—all built around your ideas for your product.

All the cards can be fully customized on the back and face. We provide free design with just need your photos and images. Please note that all images should be minimum 300 DPI and include bleeding area.

Benefit from free design, digital samples validation, custom mold development, and printed sample production—all through our one-stop service for premium custom cards.

standard size:

Custom back only

provide 1 image for the back of the cards

fully bespoke on both side

provide 1 image for the back of the cards and 54 different images for the front.

both sides-Portrait corner cutout style

provide 1 image for the back of the cards and 4 or 54 different images for the front.

both sides-round picture box

provide 1 image for the back of the cards and 4 or 54 different images for the front.

Craft Your Legacy, One Card at a Time

Introducing our premium, custom-format playing cards. Whether you’re designing a bespoke card game, a unique promotional tool, or a collector’s item, we provide the perfect blank canvas for your creativity.

Uncompromising Quality & Customization

- Premium Material Choice: Select from our high-grade paper stock for that classic, authentic feel, or durable plastic for exceptional longevity and a smooth shuffle.

- Your Vision, Perfectly Printed: Showcase your artwork with precision. Choose a centered print with a crisp 3mm white border for a clean, classic look, or opt for a vibrant full-bleed print that covers the entire card face.

- Professional-Grade Finishing: Protect and elevate your cards. We offer 4 distinct printing techniques and 6 specialized surface finishes (from high-gloss to velvety matte) to ensure the perfect look, feel, and durability for your project.

Elevate the Unboxing Experience

Go beyond the cards with our range of premium packaging. For a unique promotional gift or a custom game that stands out, upgrade to our:

- Sleek Rigid Cardboard Boxes

- Premium Tin Boxes

- Fully Customizable Packaging Solutions

Turn your project into a tangible, high-quality product that makes a lasting impression.

The material of your playing cards defines their look, feel, and durability. Funway use materials below for cards production. You can also custom other materials such as kraft paper, black card paperHere’s a simple guide to help you choose:

240-350gsm black core paper

(Top-tier anti-cheating, extremely durable, but highest cost)

Black Core paper is crafted by laminating a black opaque adhesive core between two layers of paper. This unique construction features an additional black layer precisely embedded at the very center of the cards. It blocks light rays from shining through your cards. It also makes it extremely difficult to see through the cards from the side, preventing marks and ensuring fairness. it offers a superb balance of flexibility and snap, perfect for shuffling and flourishing. This advanced construction makes it the most premium and expensive option available in core papers.

240-350gsm blue core paper

(Excellent anti-cheating properties, highly durable, cost lower than black core yet still relatively high)

Blue Core paper is crafted by laminating a blue opaque adhesive core between two layers of paper. This unique construction features an additional blue layer precisely embedded at the very center of the cards. The light transmission and durability are still excellent, though slightly inferior to those of black core paper. Reasonably priced, it is a great choice for making playing cards.

240-350gsm white core paper

(More prone to show-through, well-balanced overall characteristics, offering the best value for money)

White Core paper features a classic, tri-layer construction with an opaque white adhesive core laminated between two paper faces. This design incorporates a central white layer for consistency. While it does not offer the premium opacity of black and blue core papers and may be susceptible to show-through under strong light, it provides reliable durability that surpasses gray core alternatives. It also ensures exceptionally vivid color reproduction for all graphics. This balance of performance and cost makes it an excellent, value-driven choice for playing cards and game cards.

240-350gsm gray core paper

(Better light transmission than white core, though less durable, with the lowest cost.)

Gray Core paper features a gray, opaque center layer laminated between two paper faces. This construction offers a balance of basic opacity and cost-effectiveness, with its light transmission falling between White and Blue Core varieties. While its durability is not as high as that of white Core paper, it stands as the most budget-conscious choice available. This makes it an ideal solution for promotional giveaways, or any project where maximizing value is the primary goal.

C2S Coated Paper

(Superior printing quality, smooth texture, but susceptible to damage)

C2S Coated paper is manufactured by applying a smooth coating to both sides of high-quality paper. This unique double-sided finish creates an exceptionally bright and uniform printing surface, allowing graphics and colors to appear exceptionally vivid and sharp. While it offers outstanding visual results, it is less flexible than core papers and more susceptible to creasing and moisture. Ideal for artistic decks, collector’s editions, and promotional sets where visual appeal is the top priority, C2S paper delivers premium image quality at a mid-range price.

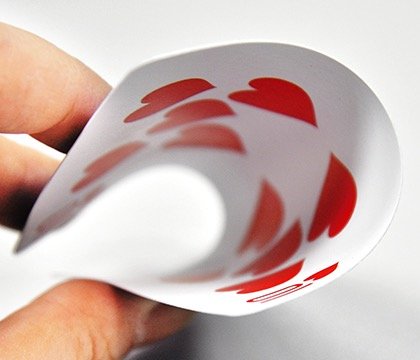

PVC plastic

(100% waterproof, with a premium and luxurious feel)

PVC Plastic is produced through a synthetic molding process, creating a fully polymer-based material without any paper layers. This homogeneous construction makes it entirely waterproof, stain-resistant, and highly resistant to tearing and deformation. Its durability far surpasses all paper-based options. As the most resilient and long-lasting choice, PVC plastic is suited for frequent use in humid environments, outdoor events, casinos, and high-end custom decks where extreme durability is required. It also can be used to design transparent cards.

Elevate your brand with four printing options, designed to deliver a premium, custom aesthetic.

Full color printing: the most economical and reliable choice

For full color cards, to achieve a deep, rich, and true-to-life color spectrum, we utilize two precision printing methods: digital printing for limited editions and small runs, and offset printing for high-volume mass production. Both ensure exceptional color fidelity and vibrancy.

Gold/Silver foil stamping printing: high-quality and high-end

Gold/Silver foil stamping printing adds an extra elegant and expensive-looking touch to your deck of cards. It is the definitive way to turn any cards into a luxury deck and to give your custom cards a unique edge compared to others.

Spot UV printing: Showcases a sharply elevated pattern with a pronounced 3D look

Spot UV printing applies a high-gloss, clear coating to specific areas of your cards, creating a striking contrast between the vibrant, matte paper and the raised, reflective gloss. This technique adds a sophisticated texture and visual depth.

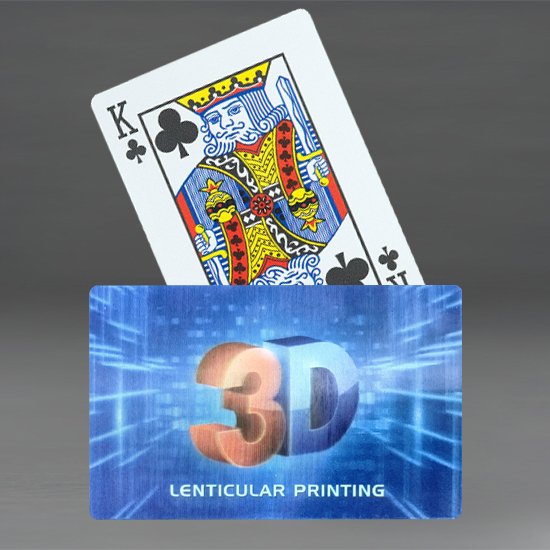

3D lenticular printing: provide things out of the ordinary

3D lenticular printing brings your custom cards to life with captivating motion and depth effects. By overlaying a specialized lens on a precisely printed interlaced image, this advanced technology creates the illusion of animation, morphing, or a stunning three-dimensional view.

Elevate your brand with 6 surface finishing options, let you custom cards more premium and aesthetic.

Glossy Varnish

A glossy varnish is a clear, liquid coating applied to the printed surface, which is then typically air-dried or cured with UV light. Its primary function is to provide a protective layer that guards against scuffing, fingerprints, and minor abrasions. Visually, it significantly enhances the vibrancy and saturation of the underlying inks, making colours appear richer and more intense.

It creates a reflective, shiny surface that gives the paper a slick, polished look. This finish is often chosen for projects where a vibrant, eye-catching appearance is desired. However, its highly reflective nature can sometimes cause glare under bright lights, potentially affecting readability.

Matte Varnish

matte varnish, also a liquid coating, serves a similar protective purpose as its glossy counterpart but offers a completely different aesthetic and tactile experience. It dries to a non-reflective, velvety smooth finish that eliminates glare, making it an excellent choice for understated branding. It provides a sophisticated and premium feel that is often associated with high-end products.

While it protects against scuffs, the matte surface can sometimes be more susceptible to showing fingerprints or smudges compared to a gloss finish. It is particularly valued for its ability to enhance readability and provide a subtle, tactile depth to the design without altering the colour tones with added shine.

Glossy Lamination

Glossy lamination involves thermally bonding a thin, clear plastic film (usually polypropylene) to the entire surface of the printed sheet. This process creates an exceptionally durable and robust barrier that is highly resistant to water, moisture, tearing, and heavy abrasion. The gloss film intensifies colours to a degree similar to gloss varnish but with a more pronounced and physically resilient shine.

It is the go-to choice for items that require maximum durability and a high-impact visual finish. The film effectively seals and protects the printed piece, significantly extending its lifespan.

Matte Lamination

Matte lamination applies a non-glossy plastic film to the paper, offering the same superior level of physical protection as glossy lamination—including resistance to water, tearing, and scratches—but with a premium, tactile quality. The finish is smooth and silky to the touch, providing an exceptionally sophisticated look and feel that minimizes light reflection and glare.

It is highly effective at concealing fingerprints and minor surface imperfections. This makes matte lamination a preferred option for luxury cards, packaging and any application where a refined, understated elegance and durability are paramount.

Embossing

Embossing is a finishing technique that uses a male and female die set to press the paper from both sides, creating a raised, three-dimensional design on the surface. This process does not involve adding ink or colour but relies on the play of light and shadow to highlight logos, patterns, or text. It adds a profound tactile dimension and a tangible sense of quality and depth to the printed material.

Embossing can be combined with other techniques like foil stamping or spot varnish to further accentuate the raised area, making it a powerful tool for creating emphasis and a memorable, luxurious sensory experience on items.

Debossing

Debossing is the opposite of embossing. It uses a similar die-stamping process, but instead of raising the paper, it presses the design down into the surface, creating a recessed impression. This technique impresses a permanent, indented mark that conveys a sense of permanence and craftsmanship. Like embossing, it is a tactile process that enhances the perceived value of the product through touch.

Debossing can be used on its own for a subtle, elegant effect, or it can be paired with a fill such as coloured foil or ink (a technique known as “blind debossing” when no colour is added).

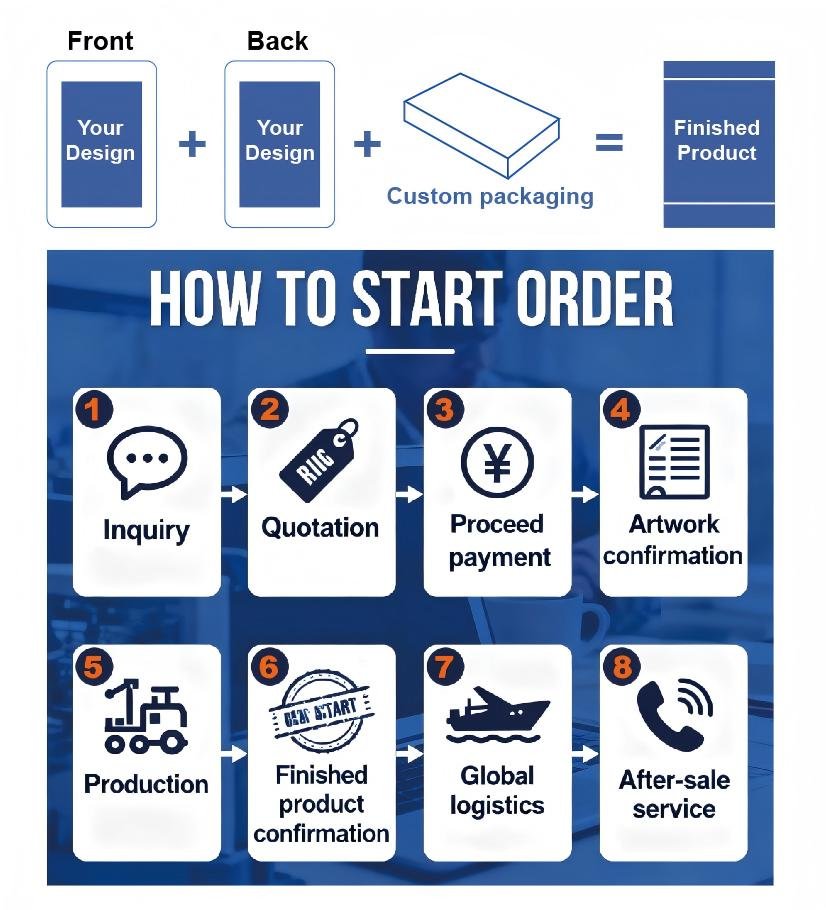

Customization Process

Phase 1: Consultation & Planning

Phase 2: Design & Confirmation

Phase 3: Production & Quality Inspection

Phase 4: Delivery & After-Sales Service

Accessories

Elevate your cards with our selection of fun and playful accessories. These add-ons are the perfect way to enhance the user experience and create a memorable product. Funway offers a range of standard options, and we also love bringing custom ideas to life.

See other card types

Card size

- Game cards

- Bridge size playing cards

- Poker size playing cards

- Big playing cards

- Tarot cards

- Mini size playing cards

- Giant size playing cards

- 100% plastic cards

- Transparent cards

- Pinochle playing cards

- Trump cards

- See more…

Custom type

- Custom back

- Custom face and back

- Custom blank cards

- Custom back (text only)

- Complete custom requirements?

Card type

- Wedding playing cards

- Monogrammed cards

- Lenticular cards

- Braille playing cards

- TCG token/cards

- Sports cards

Accessories

- Card box & packaging

- Blank card decks

- Brick boxes

- Uncut sheets

- Sticker seals

- Booklets

- Tarot cloth

- Chips

- Card sleeves

- Card clips

- Sample pack

1,638+

Commercial Projects

who we are

Your ultimate board game manufacturer

Dongguan Funway has been the trusted ODM/OEM expert for brands seeking top-quality custom board games, card games, puzzles, and packaging solutions. We bring creativity to life through integrated one-stop services

Our factory is equipped with over 16,000+ sqm dedicated facility and 200+ skilled team members. We have a ready mold here to meet your specific needs.

Call US

+86 135 7085 3827