Custom Game Mats and Game Screens

The physical environment of a tabletop game—defined by the surfaces players touch and the barriers that protect hidden information—directly impacts gameplay immersion and ergonomic comfort.

At Funway, we manufacture game mats and screens as environmental hardware, engineered for structural stability, surface precision, and long-term durability rather than decorative printing.

We Provide All options for Game Mats & Screen

Professional Neoprene & Fabric Game Mats

(Focus: Odor Control, Surface Friction & Edge Durability)

A game mat is more than a printed surface. It functions as a friction-controlled interface that protects cards, stabilizes components, and supports smooth, repeatable player interaction.

Material Engineering & Odor Control

We utilize high-density, de-odorized neoprene (SBR / SCR) as the core material.

A dedicated post-production venting and stabilization process significantly reduces the residual rubber odor commonly found in low-grade mats, ensuring a retail-ready, out-of-box experience.

Surface Friction Control

The surface is laminated with ultra-smooth polyester fabric, calibrated for low-friction card sliding. This allows players to pick up, slide, and fan cards without surface snagging or drag. Surface texture is controlled to balance:

- Smooth card movement

- Stable component placement

- Long-session handling comfort

Edge Durability & Anti-Fraying Construction

Unprotected mat edges are a primary failure point under repeated rolling and transport.

To prevent fabric delamination and edge curl, we offer high-density stitched edge binding (overlocking). This reinforces the perimeter and maintains structural integrity through thousands of roll and unroll cycles.

Anti-Slip Base Stability

The rubber backing features a multi-directional traction pattern to anchor the mat securely to the table surface, minimizing shift during active gameplay.

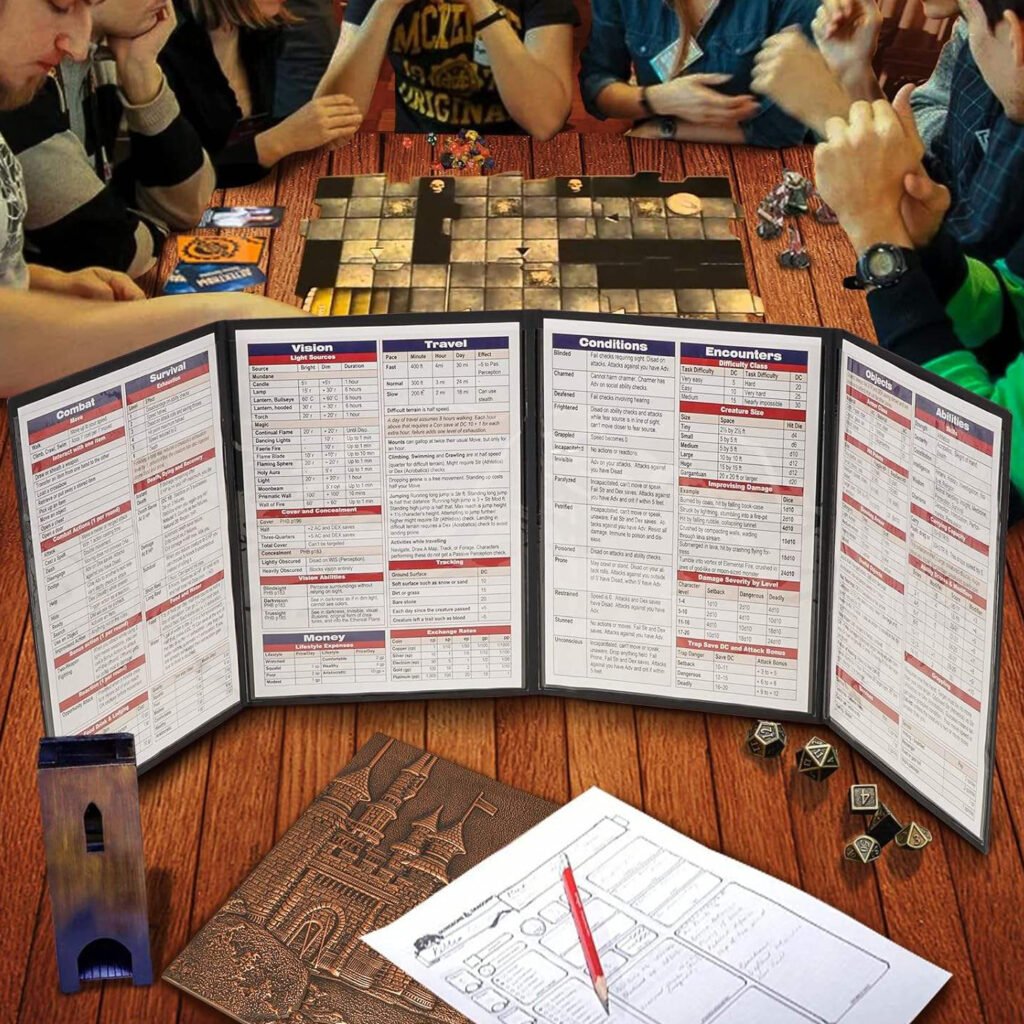

Structural Tactical Game Screens

(Focus: Standing Stability, Fold Longevity & Privacy Control)

Game screens serve as privacy barriers and information-management tools. Their performance is defined by how reliably they stand, how long fold points survive, and how effectively they block visual bleed-through.

Core Rigidity & Warp Resistance

Screens are constructed using multi-layer, high-density greyboard (2.0–3.0 mm) to ensure vertical stability without bowing or tipping.

Balanced lamination on both sides of the board minimizes internal tension, reducing environmental warping over time.

Hinge Engineering & Fold Longevity

The fold line is the primary structural failure point of any game screen.

To extend folding life, we utilize reinforced linen or polymer-based joint systems that distribute stress across the hinge zone. This allows for thousands of smooth open–close cycles without outer litho-wrap cracking or surface tearing.

Opacity & Privacy Performance

Each screen is engineered with a zero-light-bleed core, preventing information visibility even under strong overhead lighting. Board density and lamination structure are tuned to maintain full opacity without excessive weight.

Functional Layout Options

We support multiple structural configurations, including:

- 3-panel and 4-panel layouts

- Landscape or portrait orientations

- Precision die-cut silhouettes for clean, professional edges

- Layout selection is reviewed alongside stability and folding requirements to ensure consistent table performance.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Manufacturing Rigor: Performance & Integration

High-Fidelity Surface Printing (Game Mats): For game mats, we employ thermal transfer sublimation printing, bonding ink directly into the fabric fibers. This prevents cracking, peeling, or fading and allows mats to remain washable under controlled conditions.

Screen Printing & Surface Protection (Game Screens): Game screens are printed using offset or lithographic processes on C2S paper surfaces. Protective coatings are applied to reduce surface wear and minimize ink degradation along fold lines during repeated use.

Cross-Component Color Consistency: Color synchronization is maintained between screens, mats, and other printed components (boxes, cards) through color management, reducing visual drift across the full game set.

Safety & Compliance: All rubber, polymer, and laminated materials are tested for volatile organic compounds (VOCs) and comply with EN71 and REACH standards, ensuring safety for prolonged skin contact during gameplay.

Integration with Game Production

Game mats and screens are reviewed alongside box dimensions, insert layouts, and core component storage.

This ensures screens store flat without hinge stress, and mats roll or fold without long-term deformation.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!