Custom Playing Cards for

Board Games & Tabletop Games

Engineered for durability, shuffle performance, and long-term play

Custom playing cards(game cards) are not simply printed paper products—they are precision-manufactured game components. We provide industrial-grade manufacturing solutions where card stock composition, coating chemistry, and cutting accuracy are engineered as a unified production system to ensure long-term durability and consistent shuffle feel.

Whether producing standard decks for board games or high-opacity collector editions, our process balances structural elasticity with surface texture. Utilizing FSC-certified cardstock and production-proven finishing processes, we deliver a crisp “snap” and edge-wear resistance suited for high-frequency gameplay and professional collectors.

We Provide All options for Custom Playing Cards

Custom Card Size Options & Standard Formats

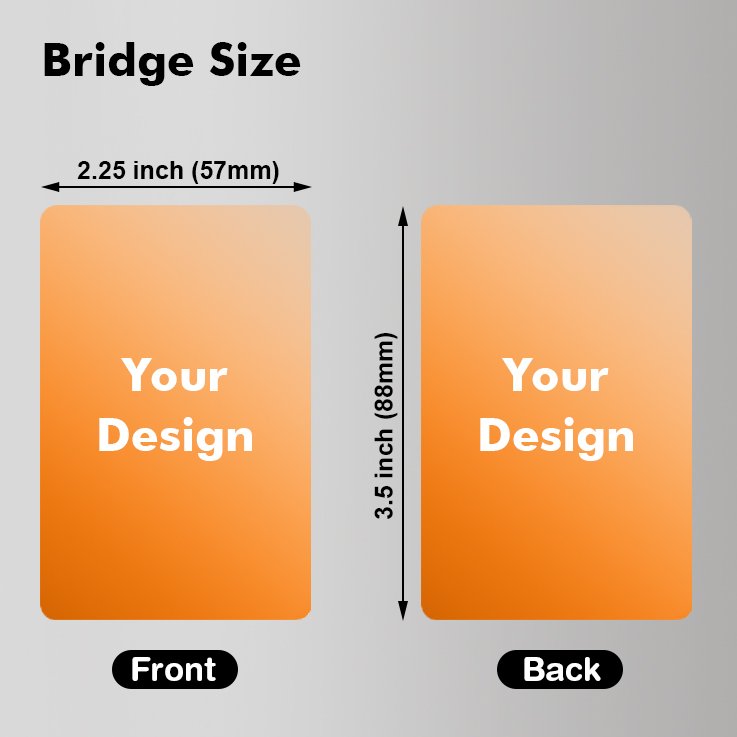

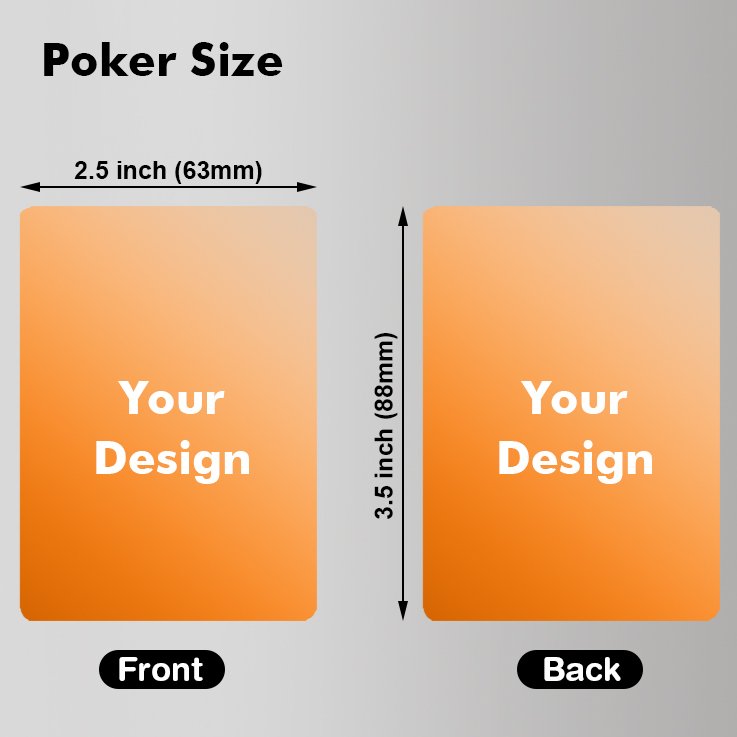

Selecting the correct card size is a foundational decision that impacts gameplay ergonomics and tooling efficiency. We support both industry-standard formats and fully custom dimensions, engineered to integrate seamlessly with downstream production processes.

Standard Card Size

We manufacture all commonly used card formats for board games, card games, and tabletop products, including but not limited to:

Poker Size: 63 × 88 mm / 2.5 × 3.5 inch: The most widely adopted format for modern board games and card-driven mechanics.

Bridge Size: 57 × 88 mm / 2.25 × 3.5 inch: Preferred for games requiring easier hand management and reduced fan width.

Tarot Size: 70 × 120 mm / 2.75 × 4.75 inch: Commonly used for tarot decks, narrative-driven games, and titles requiring large-format illustrations or text-heavy layouts.

Mini / Euro Size: 44 × 68 mm / 1.75 × 2.65 inch: Ideal for compact games, travel editions, and titles with large card counts.

Square & Specialty Sizes:Common in deduction games, icon-driven systems, and abstract mechanics.

These formats utilize proven die libraries, enabling faster setup and cost-efficient tooling.

Custom Card Sizes

For games with unique layout requirements or bespoke visual design, we offer fully custom card dimensions.

Flexible Aspect Ratios: Custom widths and heights can be engineered to support specific artwork compositions or icon hierarchies.

Gameplay-Driven Sizing: Card size can be optimized for hand comfort, table footprint, or multi-card interaction mechanics.

Custom sizes are evaluated at the pre-production stage to ensure compatibility with printing, coating, and cutting workflows.

Tooling & Die Compatibility: Card dimensions directly affect die design and tooling reuse.

Standard Size Advantage: Using established formats allows reuse of existing cutting dies, reducing tooling cost and lead time.

Custom Die Engineering: New dimensions require dedicated steel dies, which are engineered for repeatability across long production runs.

Our engineering team reviews each size specification to balance design freedom with manufacturing efficiency.

Card Thickness, Weight & Flex Profile

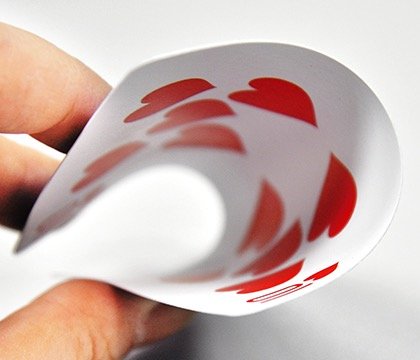

Card thickness is a critical ergonomic factor that impacts shuffle feel, snap recovery, and player fatigue. We help you select the optimal grammage based on your deck size and gameplay mechanics.

Common Card Specifications

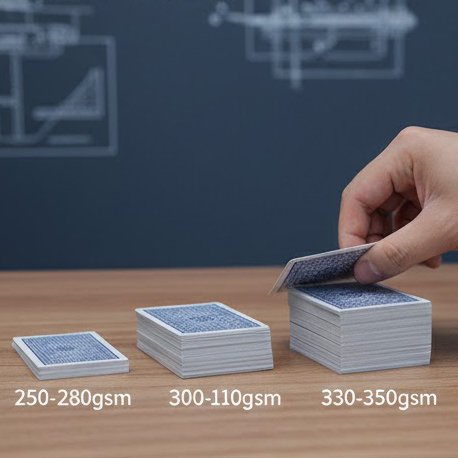

250–280gsm (Approx. 0.26–0.28mm): Ideal for party games or games with 200+ cards where deck height must be managed.

300–310gsm (Approx. 0.30–0.32mm): The industry standard for modern board games; balances durability with ease of shuffling.

330–350gsm (Approx. 0.34–0.38mm): Premium collector grade; offers maximum “snap” and a heavy, high-end hand feel.

Engineered Flex Performance & Shuffle Durability

Each card stock specification is validated against the following performance criteria:

- Snap Recovery: The card must return to a perfectly flat state after a 90-degree flex, ensuring no permanent warping

- Edge Resilience: Specifically engineered to resist “mushrooming” or splitting during aggressive riffle and overhand shuffles.

- Stack Stability: Balanced friction coefficients to ensure large decks remain stable on the table without sliding.

Thickness tolerances are strictly monitored via calibrated digital micrometers to prevent any “mixed-feel” variations between production batches.

Playing Card Materials & Cardstock Engineering

Card performance is defined by internal paper construction rather than surface appearance alone. Different core structures directly affect opacity, durability, shuffle behavior, and unit cost. At Funway, we manufacture playing cards using a full range of paper and plastic substrates to match gameplay mechanics, handling frequency, and budget constraints.

Below are the six primary material options we offer for custom playing cards and board game cards.

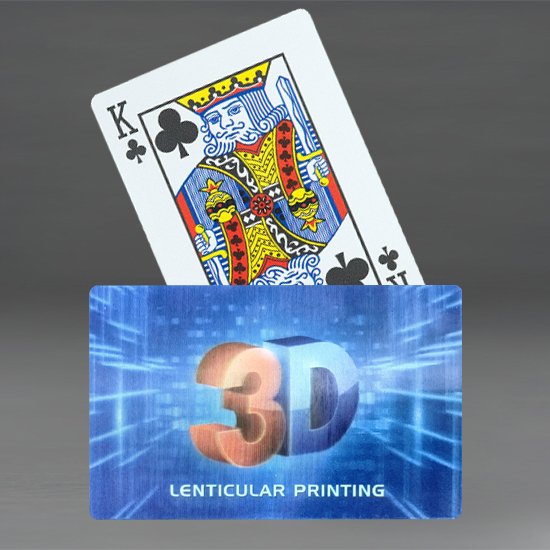

Custom Playing Cards Printing Methods & Specialty Effects

Printing quality directly impacts color accuracy, edge clarity, and long-term surface durability. We engineer each printing method based on production volume, artwork complexity, and finishing compatibility to ensure consistent results from proofing to mass production.

At Funway, we support four primary printing technologies for custom playing cards, each optimized for specific design, production volume, and cost objectives.

Surface Finishes & Texture Treatments

Surface finishing directly affects card handling, glare control, abrasion resistance, and long-term durability. We apply finish systems at controlled thickness and curing parameters to ensure consistent tactile performance across every deck. Finish selection is engineered in coordination with cardstock, printing method, and intended gameplay intensity.

Soft Touch Lamination

Soft touch lamination is a premium specialty film engineered to deliver a distinct tactile experience. It cures to an ultra-matte, non-reflective surface with a velvety, suede-like feel that immediately communicates high perceived value.

This finish enhances color depth without gloss glare, making artwork appear richer and more controlled. While it provides effective protection against moisture and edge fraying, its soft surface requires careful handling, as it can be more sensitive to oils or deep scuffs compared to hard-coat laminations.

Engineering characteristics:

Ultra-matte, non-reflective surface

Distinctive soft-touch tactile response

Durable barrier with higher cosmetic sensitivity

Recommended for:

Deluxe editions, Kickstarter premium tiers, and boutique game releases.

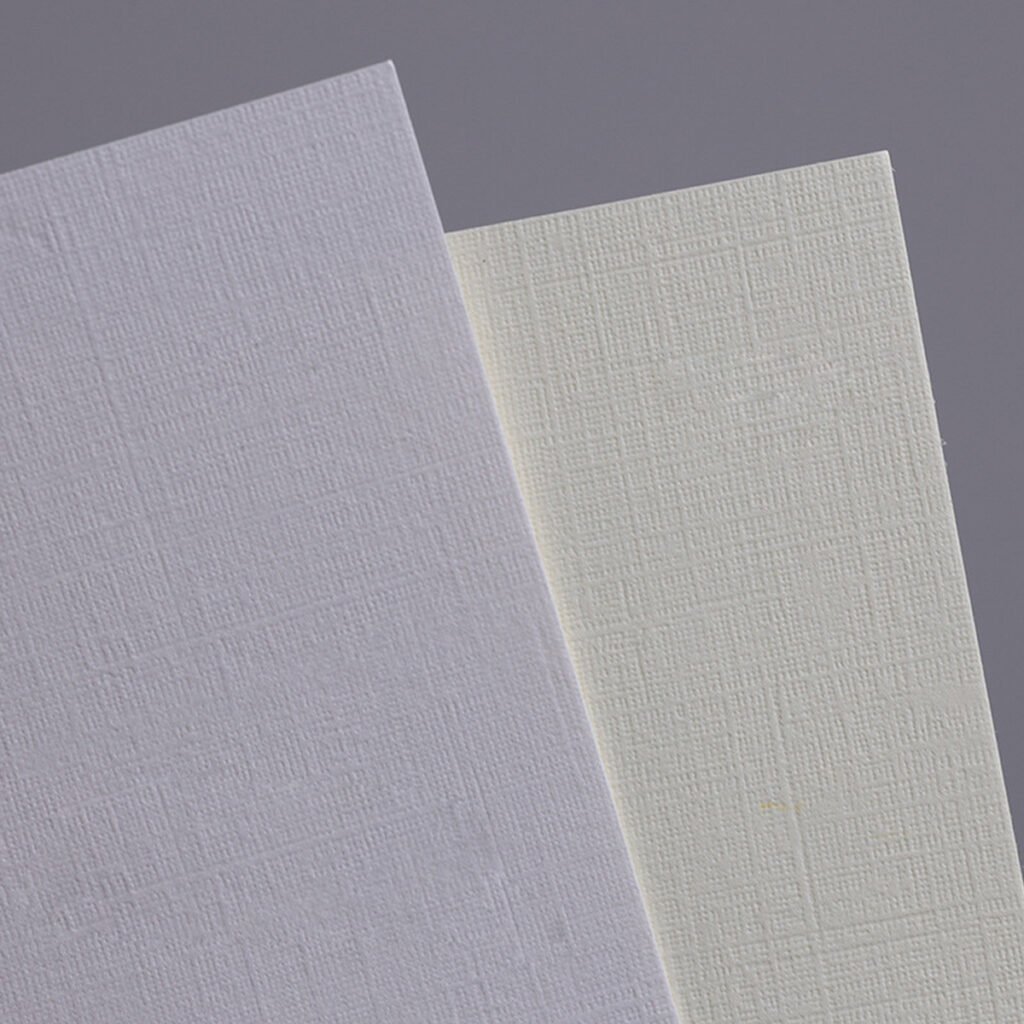

Linen Finish (Embossed Texture)

Linen finish introduces a micro-embossed texture that mechanically reduces surface contact between cards.

Rather than relying solely on coatings, this texture improves airflow and separation during shuffling, especially in humid environments.

Engineering characteristics:

Improved shuffle separation

Reduced sticking

Requires specialized embossing rollers during the finishing stage

Recommended for:

Traditional playing cards and shuffle-intensive games.

Glossy Varnish

Gloss varnish applies a thin, transparent protective layer that enhances color saturation and surface smoothness without significantly altering card thickness. This finish delivers a crisp visual presentation and balanced shuffle performance, making it a cost-efficient choice for high-volume production.

Engineering characteristics:

- Enhances color contrast and ink clarity

- Low added thickness, minimal impact on flex profile

- Moderate abrasion and moisture resistance

Recommended for:

Standard board game cards, mass-market decks, and cost-sensitive projects.

Matte Varnish

Matte varnish provides surface protection while reducing light reflection, improving readability under strong tabletop lighting. Unlike lamination films, varnish maintains a more natural paper feel while offering basic resistance to scuffing.

Engineering characteristics:

- Non-reflective visual finish

- Preserves paper texture

- Lower surface hardness than lamination

Recommended for:

Strategy-heavy games and designs prioritizing legibility over gloss.

Glossy Lamination

Gloss lamination encapsulates the card surface with a polymer film, significantly increasing durability and moisture resistance. This finish delivers smooth shuffle behavior and high visual impact, particularly for artwork-driven decks.

Engineering characteristics:

- High abrasion and moisture resistance

- Low friction coefficient for smooth shuffling

- Increased card stiffness depending on film thickness

Recommended for:

Playing cards, party games, and decks with frequent shuffling.

Matte Lamination

Matte lamination uses a polymer film to control glare while improving surface hardness and edge durability. Compared to matte varnish, lamination offers superior protection but slightly higher shuffle friction.

Engineering characteristics:

- Strong surface protection

- Reduced glare under overhead lighting

- Slightly increased handling resistance

Recommended for:

Premium board games and collector-oriented products.

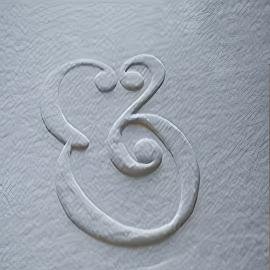

Embossing(Raised Surface Detailing)

Embossing mechanically raises selected design elements above the card surface using precision metal dies. This process creates tactile highlights that enhance both visual hierarchy and brand recognition without relying on ink thickness or surface coatings. Embossed elements remain physically present throughout the card’s lifespan, ensuring that logos, symbols, or focal graphics do not fade or flatten with repeated handling.

Engineering characteristics:

- Raised texture formed during die-press stage

- Requires controlled paper recovery and coating compatibility

- Best applied before lamination or combined with soft-touch films

Recommended for:

Card backs, logos, suit symbols, and premium branding accents where tactile visibility is desired.

Debossing (Recessed Surface Detailing)

Debossing presses selected artwork into the card surface, creating a recessed impression that adds subtle depth and refined texture. Unlike embossing, debossed elements sit below the surface plane, offering a more understated and elegant tactile response. This technique is particularly effective when paired with matte or soft-touch finishes, allowing light and shadow to naturally define the recessed areas without visual clutter.

Engineering characteristics:

- Recessed texture formed via reverse die pressure

- Maintains flat surface edges for smoother stacking

- Requires precise pressure control to avoid fiber cracking

Recommended for:

Minimalist designs, luxury decks, and card faces where restrained texture enhances sophistication without affecting shuffle performance.

Can’t find what you want? Contact us!

We’re always happy to discuss new formats or unusual specifications. If you don’t see what you’re looking for above, get in touch. Our team will be glad to help.

Custom board games possess

At Funway, board game production is managed as an integrated manufacturing system, not a collection of independent components. From early-stage consultation through engineering review, sampling, and mass production, each project is supported by a dedicated manufacturing team that works closely with your specifications, files, and component decisions. This consultative approach ensures that design intent remains manufacturable as the project moves from custom board game prototype to mass production.

Rather than treating manufacturing as a handoff after design, we coordinate decisions across the board game supply chain—component definition, tooling release, sampling approval, and production sequencing—to reduce variance, prevent late-stage rework, and maintain consistency throughout production.

Die-Cutting Accuracy & Edge Durability Control

Card cutting quality directly determines deck uniformity, shuffle performance, and long-term durability. We treat die-cutting as a single integrated engineering process—controlling dimensional accuracy, cutting geometry, and edge structure in one coordinated system.

Dimensional Tolerance & Deck Uniformity

Consistent card dimensions are critical for fair gameplay and smooth handling, especially in large decks.

Tight Size Tolerances: In each production run, card length and width are controlled within ±0.35mm to prevent deck misalignment, uneven stacking, or fit issues with tuck boxes and cellophane or shrink wrapping.

Deck Height Stability: Accurate thickness and size control ensure large decks remain manageable and compatible with standard tuck boxes and rigid packaging.

All cutting dies are regularly calibrated and inspected to maintain consistency across the full production lifecycle.

Die-Cutting Geometry & Corner Precision

Cutting geometry directly affects shuffle smoothness and wear patterns.

Optimized Corner Radii: Standard options include 3mm, 4mm and 5mm, and custom radii selected based on card size, thickness, and intended shuffle style.

Wear-Reduction Design: Properly engineered corners minimize edge catching and significantly reduce premature corner whitening during riffle and overhand shuffles..

Edge Locking (Fiber Compression) Process

To enhance long-term durability, we offer an optional edge locking (fiber compression) process during die-cutting.

Reduced Edge Fraying: Compressed fibers resist fuzzing, splitting, and delamination caused by repeated handling.

Improved Moisture Resistance: Sealed edges limit moisture penetration into the card core, extending card life in humid or high-use environments.

This process is strongly recommended for party games, competitive card games, and decks designed for frequent, aggressive shuffling.

Cost Drivers & MOQ Optimization

Unit cost for custom playing cards is primarily determined by a small set of controllable production variables. Optimizing these factors early allows publishers to balance premium feel with manufacturing efficiency.

Core Material Selection

Black core paper carries the highest cost due to its dense, light-blocking structure. Blue and white core options offer strong performance at lower cost tiers, while gray core and C2S are specified for budget-driven projects.

Deck Size & Card Count

Standard 54-card decks achieve the highest production efficiency. Custom card counts are fully supported, though non-standard quantities may affect material yield and per-unit cost.

Special Finishing Effects

Processes such as full-face foil film, spot UV, embossing, or gilded edges require additional production passes and tooling, directly increasing unit price. These effects are typically reserved for deluxe or collector editions.

Packaging Complexity

Tuck box materials, internal printing, custom seals, and specialty papers influence both material and assembly costs. Simplified packaging improves MOQ flexibility, while premium packaging elevates perceived value.

FAQ

Contact

Launching a custom board game can be a complex and challenging process, involving dozens of decisions. We’re committed to making your board game design, printing, and manufacturing process as easy and convenient as possible. But if you have any further questions, please feel free to contact me.

We’re happy to answer all your questions about custom board game printing and manufacturing and can provide you with a quote tailored to your requirements without any obligation. Feel free to contact us—we’re always here to help!